Dek . 24, 2024 17:10 Back to list

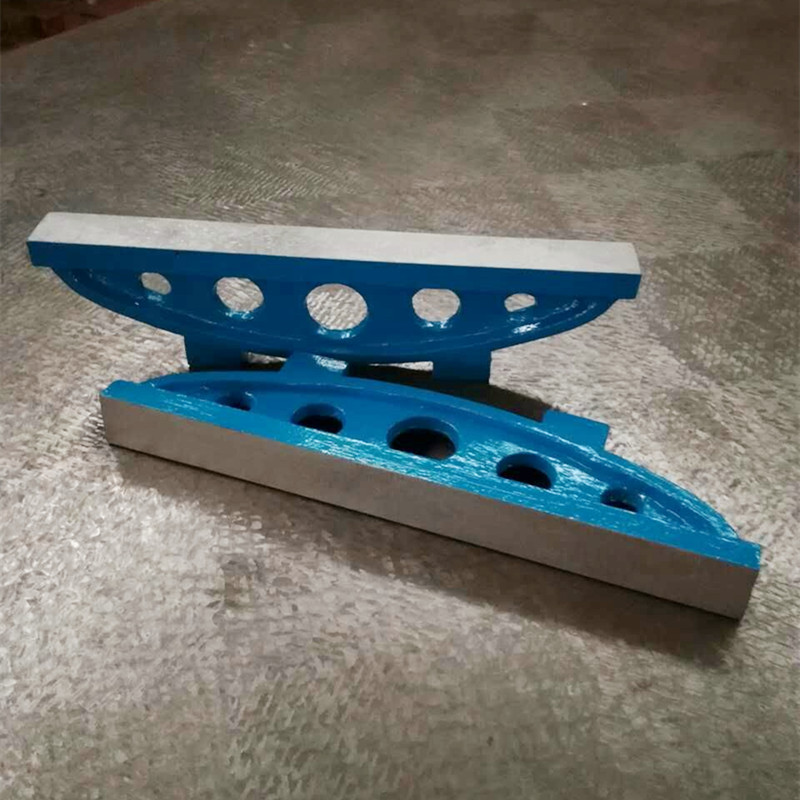

thread ring gauge go no go

Understanding Thread Ring Gauge Go and No-Go Measurements

In the world of precision manufacturing and engineering, ensuring the accuracy and reliability of threaded components is crucial. One of the key tools used for this purpose is the thread ring gauge. This article explores the concept of thread ring gauges, specifically focusing on the Go and No-Go standards.

What is a Thread Ring Gauge?

A thread ring gauge is a cylindrical tool used to assess the thread dimensions of a workpiece. It is designed to provide a definitive measurement of the thread’s pitch, diameter, and profile. Thread ring gauges come in pairs the Go gauge and the No-Go gauge. Together, they help ensure that threaded components meet strict tolerances, which is vital for the interchangeability and functionality of parts in various applications.

The Go Gauge

The Go gauge is the first of the pair used in the measurement process. Its primary purpose is to confirm that the workpiece’s threads are within acceptable limits. The Go gauge should fit onto the threaded part without excessive force. If the gauge fits easily, it indicates that the thread cut on the workpiece is acceptable regarding the major and minor diameters and the thread pitch.

The Go gauge is usually slightly larger than the minimum allowable size of the thread. This ensures that if a part passes the Go gauge test, it can be safely considered to be within acceptable tolerances for its application.

The No-Go Gauge

thread ring gauge go no go

On the other hand, the No-Go gauge serves a different but equally important role. Designed to ensure that the threaded part does not exceed the maximum allowable size, the No-Go gauge should not fit onto the threaded component. If it does fit, the thread is considered out of tolerance and requires remediation, whether that means reworking the part or scrapping it altogether.

The No-Go gauge is usually slightly smaller than the maximum allowable size for the thread. This makes it an essential tool for preventing manufacturing errors that could lead to poor assembly or malfunctions in the final product.

The Importance of Go and No-Go Gauges

The use of Go and No-Go gauges is fundamental in the quality control process of manufacturing threaded components. By using these gauges, manufacturers can ensure their components meet specified dimensions, thus allowing for proper assembly in larger systems. This is particularly important in industries where precision is non-negotiable, such as aerospace, automotive, and medical equipment manufacturing.

Another critical aspect is that using Go and No-Go gauges can help in reducing production waste. By identifying defects early in the production process, manufacturers can correct issues before they lead to significant failures, thereby optimizing operational efficiency and reducing costs.

Conclusion

In summary, thread ring gauges, specifically the Go and No-Go types, play an essential role in the quality assurance of threaded components. They provide a simple yet effective means of verifying that threads conform to specified dimensions, ensuring reliability in manufacturing processes. As industries continue to demand higher precision and quality, the importance of these gauges in maintaining operational standards will only grow. Understanding and implementing these tools is crucial for any organization committed to excellence in manufacturing.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS