Okt . 18, 2024 23:15 Back to list

Understanding Metric Trapezoidal Threads and Their Applications in Engineering Designs

Understanding Metric Trapezoidal Threads An Overview

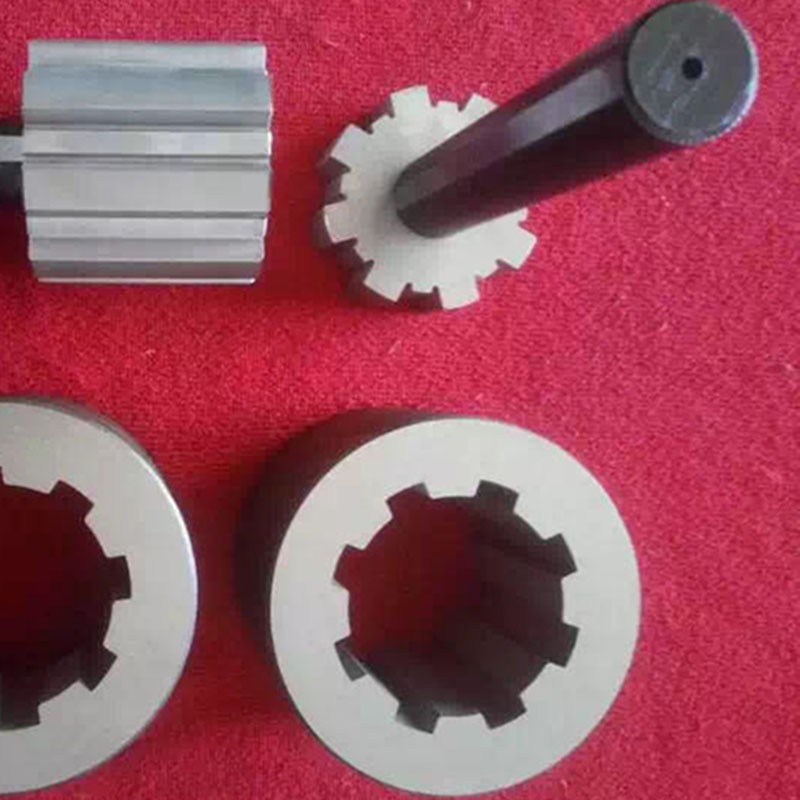

Metric trapezoidal threads are a type of threaded fastener design characterized by their unique trapezoidal shape. These threads are primarily used in linear motion applications, where they play an essential role in converting rotary motion into linear motion with minimal effort and maximum efficiency. They are commonly found in machinery, lead screws, and other devices that require precise movement.

One of the defining features of metric trapezoidal threads is their geometry. Unlike standard round threads, which have a pointed tip, trapezoidal threads have a flat top and a symmetrical, trapezoidal profile. This design increases the contact area between the threads, enabling them to bear heavier loads compared to their more conventional counterparts. The flank angle of these threads typically ranges from 30 to 40 degrees, allowing for effective load distribution and reducing the risk of stripping under stress.

The use of metric trapezoidal threads offers several advantages. First and foremost, they provide excellent backlash control. Backlash is the slight backward movement that occurs when the direction of motion is reversed. In applications where precise positioning is critical, such as CNC machines or robotics, minimizing backlash is essential. Metric trapezoidal threads, due to their design, can achieve tighter tolerances, significantly reducing this unwanted movement.

metric trapezoidal thread

Another advantage of these threads is their ability to handle axial loads effectively. This is particularly important in applications where the load is applied along the screw's axis, such as in clamps or lifting mechanisms. The trapezoidal design allows for greater friction between the engaged threads, ensuring that the fastener remains securely in place even under significant load.

In addition to their mechanical properties, metric trapezoidal threads are also standardized, which facilitates easier design and manufacturing processes. The metric system provides a universally understood set of measurements, making it easier for engineers and manufacturers across the globe to collaborate and create compatible systems. These standardized dimensions also make it simpler to replace or upgrade components, as parts are more likely to fit without requiring extensive modifications.

However, like all engineering solutions, metric trapezoidal threads also come with their own set of challenges. For instance, the installation and maintenance of these threads require precision to ensure that they perform optimally. Misalignment during installation can lead to increased wear or even failure of the mechanism. Additionally, while they offer excellent load-bearing capabilities, they may not perform as well under high-speed conditions compared to other thread types, such as ball screws.

In conclusion, metric trapezoidal threads are a crucial component in many mechanical systems, valued for their robustness, precision, and efficiency in converting rotary motion to linear movement. As technology advances, the applications of these threads continue to expand, making them a vital area of study for engineers and designers in various industries. Their standardization under the metric system further cements their importance in global manufacturing processes, paving the way for more innovative solutions in engineering design.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS