Noy . 07, 2024 15:07 Back to list

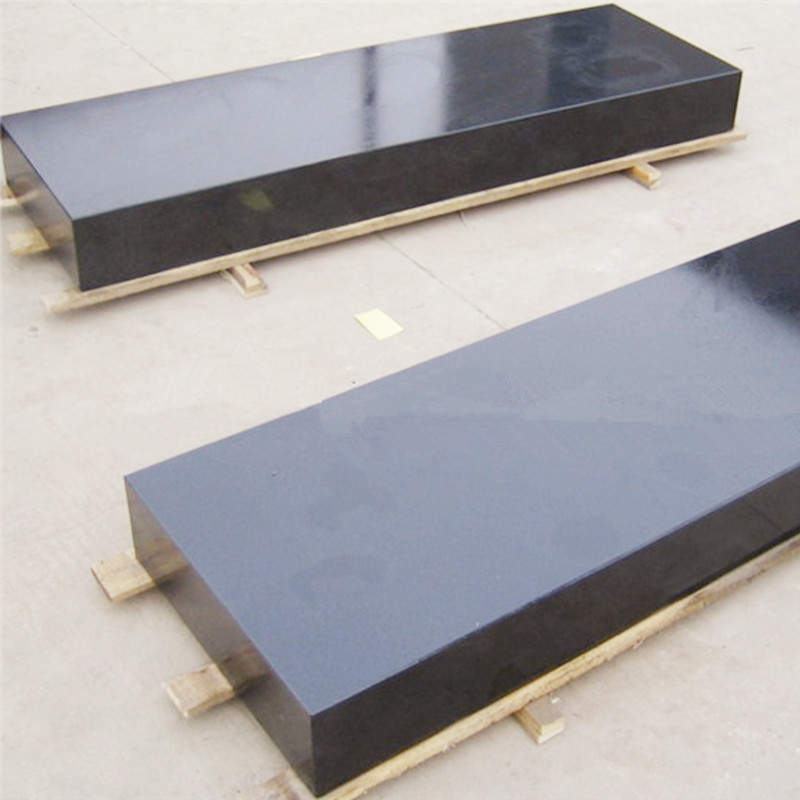

Industrial Vibration Isolation Pads for Enhanced Equipment Stability and Performance

The Essential Role of Anti-Vibration Pads in Industrial Applications

In the heart of industrial operations, maintaining equipment performance and longevity is paramount. One often overlooked yet critical component that contributes to this goal is anti-vibration pads. These specialized pads serve to mitigate vibration and noise, enhancing both the efficiency of machinery and the comfort of working environments.

Understanding Vibration in Industrial Settings

Industrial machines and equipment, ranging from large compressors to precision tools, generate vibrations during operation due to mechanical movement. These vibrations can lead to several issues machinery misalignment, increased wear and tear, equipment malfunction, and even structural damage to the facilities housing them. Furthermore, prolonged exposure to high vibration levels can pose health risks to workers, including musculoskeletal disorders.

To combat these challenges, anti-vibration pads have emerged as a practical solution within many industries. Designed to absorb vibrations and reduce noise levels, these pads are essential for maintaining operational efficiency and improving workplace safety.

How Anti-Vibration Pads Work

Anti-vibration pads are typically made from materials such as rubber, cork, or polyurethane, known for their excellent shock-absorbing properties. When placed under machinery, these pads act as a buffer, absorbing the energy produced by vibrations and preventing it from transferring to the floor and surrounding equipment. This not only protects machines but also minimizes the systemic effects of vibrations throughout the facility.

The pads are available in various shapes and sizes, tailored to the specific needs of different applications. From lightweight equipment to heavy machinery, there is a suitable anti-vibration pad designed to withstand unique loads and operational conditions.

Benefits of Using Anti-Vibration Pads

The implementation of anti-vibration pads in industrial settings offers numerous benefits

anti vibration pads industrial

1. Prolonged Equipment Life By minimizing the impact of vibrations, these pads help extend the lifespan of machinery, reducing the need for costly repairs and replacements.

2. Improved Operational Efficiency Equipment that operates with less vibration is often more precise, leading to improved product quality and consistency.

3. Noise Reduction The absorption of vibrations also helps reduce noise levels, creating a more pleasant working environment and aiding in compliance with occupational health regulations.

4. Enhanced Safety Reducing vibration levels can mitigate health risks for workers, fostering a safer workplace and lower incidence of injury.

5. Structural Integrity By preventing vibrations from transferring to the building structure, anti-vibration pads protect facilities from potential damage, ensuring safety and stability.

Selecting the Right Anti-Vibration Pads

Choosing the right anti-vibration pads is critical to maximizing their benefits. Factors to consider include the type of machinery, the weight and vibration frequency, and the operational environment. It is advisable to collaborate with experts or refer to manufacturers' guidelines to select pads that best fit your specific needs.

Conclusion

In conclusion, anti-vibration pads are a vital component of modern industrial operations. Their ability to absorb vibrations not only protects equipment but also promotes a safer, more efficient working environment. By investing in quality anti-vibration solutions, industries can enhance machinery longevity, improve product quality, and safeguard the health and well-being of their workforce. As industrial operations continue to evolve, the importance of effective vibration control measures like anti-vibration pads cannot be overstated. Embracing these tools is a critical step towards achieving operational excellence in the competitive industrial landscape.

-

Retrofitting Old Systems with Y Type Strainer ValvesNewsJun.20,2025

-

Predictive Maintenance Strategies for Industrial Butterfly ValvesNewsJun.20,2025

-

Optimizing Check Valve Types Performance in Harsh EnvironmentsNewsJun.20,2025

-

Material Selection for Ball Check ValvesNewsJun.20,2025

-

Cost-Effective Selection Criteria for Globe Gate Valve SizingNewsJun.20,2025

-

Control Valve Selection Criteria for Water Treatment PlantsNewsJun.20,2025

Related PRODUCTS