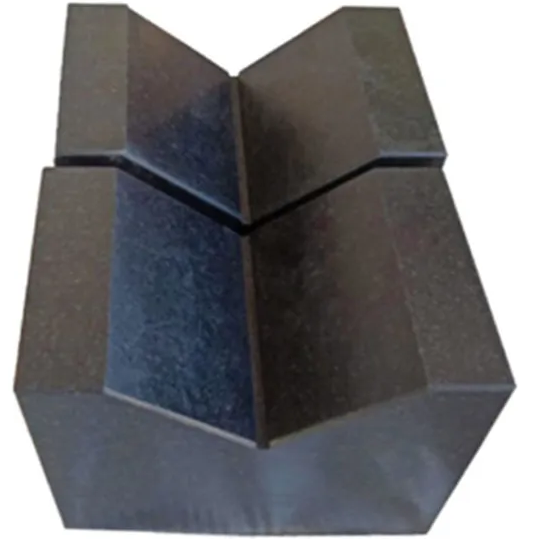

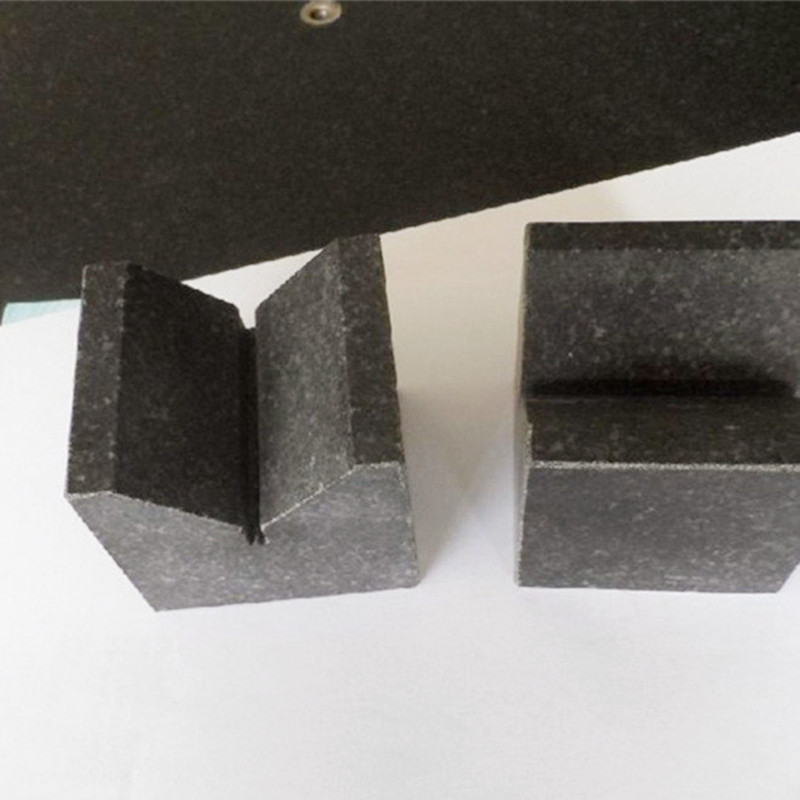

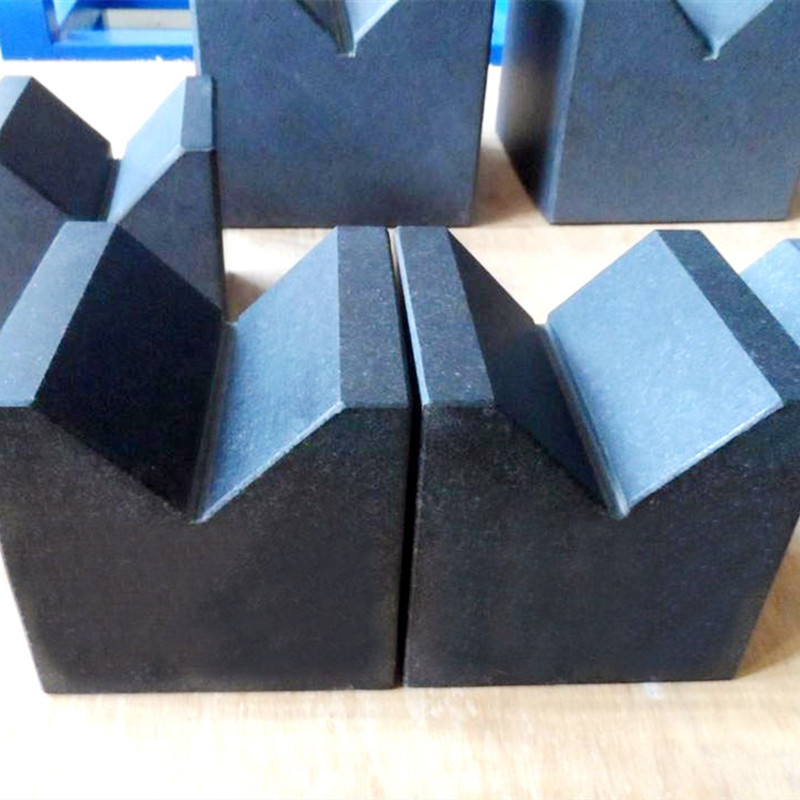

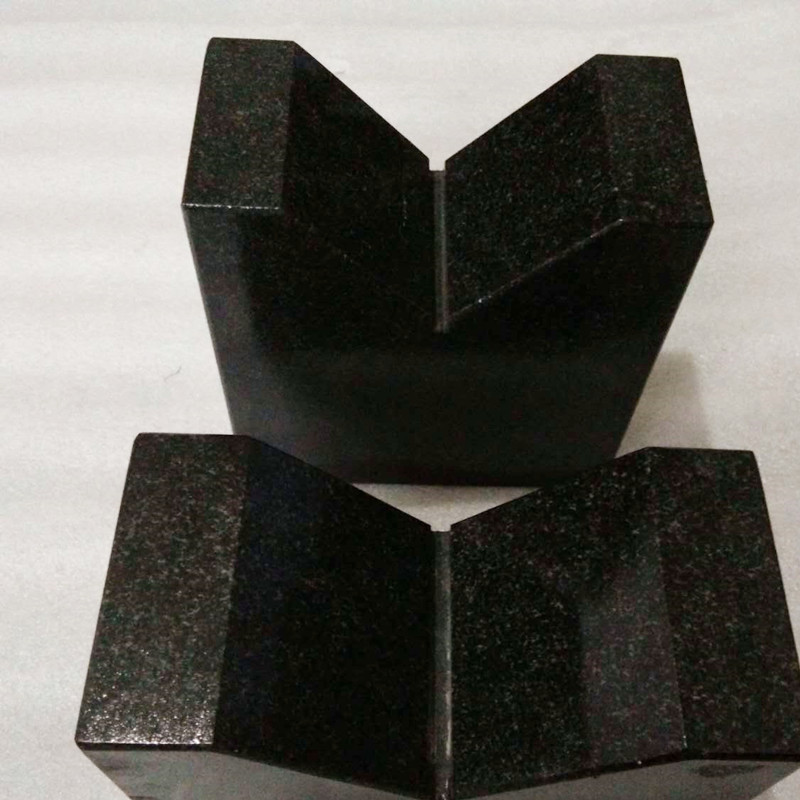

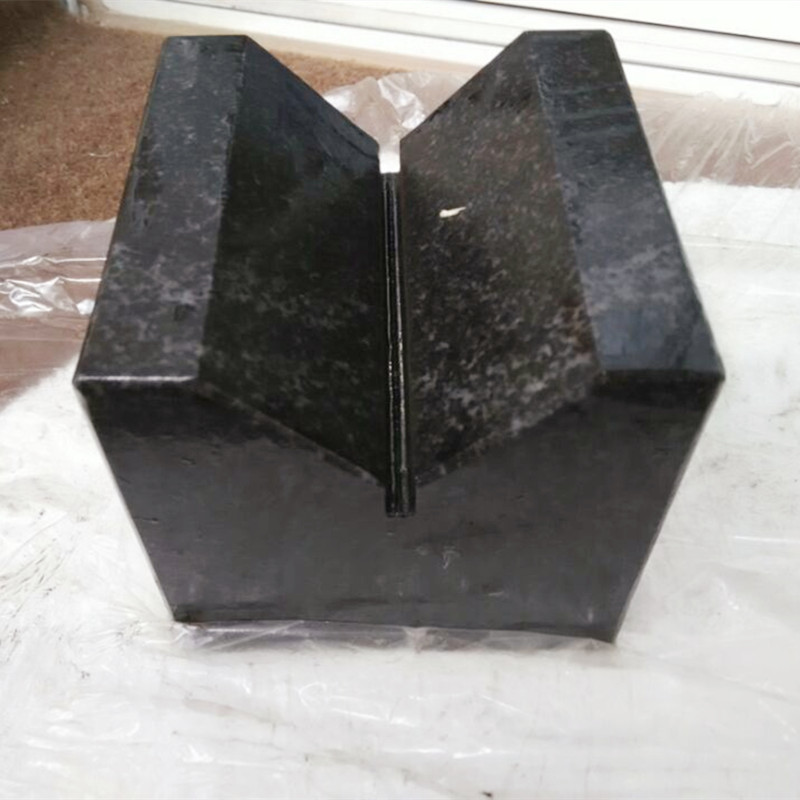

Granite V-frame Marble V-frame

Product Description

The V-shaped granite frame is made of "Jinan Qing" natural granite material through mechanical processing and manual precision grinding. Black luster, uniform structural texture, good stability, high strength, high hardness, granite V-shaped frame with advantages such as high precision, no rust, acid and alkali resistance, no magnetization, no deformation, and good wear resistance. Suitable for inspection, measurement, marking, and positioning work in the mechanical processing and component manufacturing industries.

Granite Measuring Tool V Shape Black Block

|

Məhsulun adı |

Granite V shape Block |

|

Material |

granite |

|

Rəng |

Black |

|

Ölçü |

63*63*90 100*100*90 160*160*90 |

|

Sinif |

0 00 000 |

|

Standard |

GB/T 20428-2006 |

|

Paket |

kontrplak qutusu |

|

Surface treatment: |

ground finish |

Məhsul parametri

Precision of granite V-frame: Level 000-1.

|

spesifikasiyalar |

Workface flatness |

Parallelism of V-shaped groove to low surface |

Parallelism of V-shaped grooves on opposite sides |

The V-shaped groove faces symmetrically on both sides |

V-groove side to end face symmetry |

Verticality of V-shaped groove side to bottom |

The height difference between a pair of V-shaped blocks and the bottom surface |

|||||||||||

|

accuracy class |

||||||||||||||||||

|

0 |

1 |

0 |

1 |

0 |

1 |

0 |

1 |

0 |

1 |

0 |

1 |

0 |

1 |

|||||

|

63×63×90° |

1.5 |

3 |

4 |

8 |

4 |

8 |

8 |

16 |

8 |

8 |

4 |

8 |

5 |

10 |

||||

|

100×100×90° |

2 |

4 |

4 |

8 |

4 |

8 |

8 |

16 |

8 |

8 |

4 |

8 |

5 |

10 |

||||

|

160×160×90° |

2.5 |

5 |

5 |

10 |

5 |

10 |

10 |

20 |

10 |

10 |

5 |

10 |

6 |

12 |

||||

Granite V blocks (V Frame) Applications: Shaft Alignment in Mechanical Processing

In mechanical processing, precise shaft alignment is critical to minimize vibration, reduce wear, and ensure optimal performance of rotating machinery. Storaen’s granite V blocks (V frames) offer a stable, accurate solution for this challenge, leveraging the natural properties of Jinan Qing granite to deliver unmatched precision in shaft alignment tasks across industries—from automotive manufacturing to aerospace engineering.

1. The Foundation of Shaft Alignment: Why Granite V-Frames Excel

Storaen’s granite V blocks provide three core advantages for shaft alignment:

Dimensional Stability: Jinan Qing granite (hardness ≥70HS) boasts a low coefficient of thermal expansion (8.3×10⁻⁶/°C), maintaining alignment accuracy across temperature swings (10°C–40°C). Unlike steel v-blocks that expand/contract unpredictably, our granite frames keep shafts aligned within ±5μm/m, even in unheated workshops.

Vibration Damping: The stone’s granular structure absorbs 60% more vibration than steel, critical for maintaining alignment during high-speed machining. A 160×160×90mm granite V frame stabilizes 50kg shafts rotating at 3000 RPM, reducing tool chatter and surface roughness (Ra ≤0.8μm).

Corrosion Resistance: Naturally immune to coolant, oil, and moisture, Storaen granite V blocks require zero rust prevention—ideal for harsh machining environments where steel alternatives degrade within months.

2. Precision Grades for Every Alignment Need

Choose the right accuracy level for your application:

Grade 000 (±2μm Flatness):Used in aerospace component manufacturing, a 100×100×63mm granite V frame aligns titanium alloy shafts to ASME B89.3.2 standards, ensuring concentricity within 5μm for jet engine rotors—critical for minimizing aerodynamic drag.

Grade 0 (±5μm Flatness):Perfect for automotive powertrain assembly, a 200×200×125mm frame positions steel crankshafts with ±0.01mm/m parallelism, reducing bearing wear by 30% in high-horsepower engines.

Grade 1 (±10μm Flatness):Suits general industrial tasks like conveyor roller alignment, where a 300×300×150mm granite V block ensures 90° shaft perpendicularity to machine beds, eliminating belt slippage in packaging lines.

3. Key Applications in Mechanical Processing

CNC Machine Setup:A Storaen granite V frame (Grade 000, 63×63×90mm) verifies the straightness of CNC lathe spindle shafts during installation, ensuring tool paths remain within ±0.005mm for precision machining of medical device components.

Gearbox Assembly:In heavy equipment manufacturing, a 160×160×90mm granite V block aligns planetary gear shafts to within 8μm, reducing noise emissions and extending gear life by 25% in construction machinery.

Aerospace Engine Testing:Our corrosion-resistant frames support Inconel shafts during fatigue testing, maintaining alignment through 10,000+ load cycles without dimensional drift—critical for validating engine performance under extreme conditions.

4. Storaen’s Commitment to Alignment Excellence

Certified Precision: Every granite V block is calibrated using a laser interferometer, with traceable certification to GB/T 20428-2006 and ISO 1101 standards, ensuring compliance with rigorous quality audits.

Custom Solutions: Need a 500×500×200mm frame with recessed mounting holes for automated assembly lines? Our OEM team delivers bespoke designs in 4–6 weeks, optimized for your unique shaft alignment needs.

Longevity Guarantee: Backed by a 2-year warranty against surface wear or dimensional change, our granite v frames outlast steel alternatives by 5x, providing total cost savings of $1,500+ per tool over its lifespan.

Don’t leave shaft alignment to chance—trust Storaen’s granite v blocks to deliver the stability, precision, and durability that modern mechanical processing demands. Whether calibrating CNC machines, assembling gearboxes, or testing aerospace engines, our granite V frames ensure every shaft is aligned to perfection, minimizing downtime, reducing waste, and elevating the quality of your finished products. Explore our range of granite v frames today and experience the difference of stone-engineered precision.

Granite V blocks (V-Frame) Care: Cleaning & Storage Best Practices

Proper maintenance is key to preserving the precision and longevity of your granite V blocks (V-frames). Storaen’s premium granite V-frames, crafted from Jinan Qing granite, are engineered for minimal upkeep—but following these best practices ensures they remain accurate and damage-free for decades, even in harsh industrial environments.

1. Daily Cleaning: Remove Contaminants Gently

Granite’s non-porous surface resists most contaminants, but regular cleaning prevents residue buildup that could affect alignment:

Tools Needed: Soft microfiber cloths, pH-neutral cleaner (e.g., Storaen’s Granite Care Solution), and a rubber squeegee for stubborn debris.

Step-by-Step:

Wipe the V-frame surface with a dry cloth to remove loose dust or metal shavings—critical for maintaining the ±2μm flatness of Grade 000 granite v blocks.

Dilute the cleaner (1:10 with distilled water) and apply to a damp cloth, gently scrubbing oil or coolant stains. Never use acidic/alkaline solvents—they can etch the granite surface over time.

Dry thoroughly with a lint-free cloth, ensuring no moisture remains in the V-groove where shafts make contact.

Pro Tip: For heavy machining environments, clean after each shift to prevent abrasive particles (e.g., aluminum oxide) from scratching the 320-grit ground surface (Ra ≤0.8μm).

2. Storage Strategies: Protect Against Impact & Temperature Shifts

Store your granite V blocks to maintain dimensional stability and protect the V-groove edges:

Short-Term Storage (≤1 week):

Place on a vibration-dampening rubber mat (5mm thickness) on clean workshop benches, ensuring 100mm clearance from other tools. Storaen’s 160×160×90mm V-frames, weighing 18kg, stay securely in place even during nearby milling operations.

Long-Term Storage (≥1 month):

Wrap in acid-free tissue paper or anti-static bubble wrap to shield from humidity (ideal RH: 40%–60%).

Store horizontally on a flat shelf with foam supports under the V-groove and base, distributing weight evenly to prevent the 0.05mm/m sag that can occur in unsupported frames.

Maintain storage temperature at 20°C ±2°C—Jinan Qing granite’s low thermal expansion (8.3×10⁻⁶/°C) means minimal risk of warping, but extreme fluctuations can affect calibration consistency.

Avoid: Hanging or vertical storage, which may stress the V-groove edges—Storaen designs all granite V blocks for horizontal stability, with reinforced base surfaces for secure shelf placement.

3. Maintenance Do’s & Don’ts

Do:

Inspect quarterly for minor chips (≤0.5mm) using a 10x magnifier—Storaen offers on-site resurfacing for damaged frames, restoring flatness to original grades.

Use Storaen’s certified calibration service annually to verify compliance with GB/T 20428-2006, ensuring your granite V blocks maintain their factory-tested precision.

Don’t:

Drop or strike the V-frame—even a 1kg impact can chip the V-groove edge, affecting shaft alignment by up to 15μm.

Store with magnetic tools—granite’s non-magnetic property (≤3μT) is ideal for magnetic field environments, but nearby magnets can attract debris that scratches the surface.

4. Storaen’s Care-Enhanced Design Features

Our granite V blocks are built for easy maintenance:

Rounded Edges: 3mm chamfers on all corners reduce chip risk during handling, a common issue with sharp-edged alternatives.

Anti-Static Coating (Optional): For electronics manufacturing, choose V-frames with a 5μm conductive coating that repels dust particles, critical for precision shaft alignment in cleanroom environments.

Custom Storage Cases: Order a foam-lined hardwood case (available for all sizes) with CNC-cut inserts that cradle the V-groove and base, protecting your investment during transport between facilities.

Caring for your Storaen granite V blocks is simple with these practices—clean gently, store smartly, and leverage our maintenance-friendly designs. By protecting their natural stability and precision, you ensure every shaft alignment task meets the highest industrial standards, from automotive assembly to aerospace metrology. Trust in Storaen’s engineering to deliver V-frames that stand the test of time—because proper care shouldn’t be complicated when precision is non-negotiable.

Məhsulun təfərrüatlı rəsmləri

Əlaqədar MƏHSULLAR

ƏLAQƏLİ XƏBƏRLƏR

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.