ديسمبر . 03, 2024 17:21 Back to list

Exploring the Uses and Applications of Thread Gauge Tools in Precision Engineering

Understanding Thread Gauge Tools Essential Instruments for Precision Engineering

Thread gauge tools play a critical role in the world of manufacturing, engineering, and mechanical industries. These handy instruments are specifically designed for measuring the size, pitch, and overall quality of threads on fasteners such as screws, bolts, and nuts. In this article, we will delve into the importance of thread gauge tools, their types, and applications in various industries.

What is a Thread Gauge Tool?

A thread gauge tool is a measuring device used to determine the thread specifications of fasteners. These tools can identify the thread pitch, diameter, and form, ensuring that components fit together properly. Proper measurements are essential in any engineering application, as mismatched threads can lead to mechanical failures, increased wear, and safety hazards.

Types of Thread Gauge Tools

There are several types of thread gauges, each designed for specific measurements and applications. The most common types include

1. Thread Pitch Gauge This tool consists of multiple blades or leaves, each featuring a different pitch measurement. By aligning the gauge with the thread of a fastener, users can determine its pitch accurately. Common units for measuring pitch include threads per inch (TPI) for imperial systems and millimeters for metric systems.

2. Plug Gauge A plug gauge is used to inspect the internal threads of components. It ensures that the threads meet specified tolerances. The tool is essentially a cylindrical rod with defined thread dimensions that can be inserted into the inspected fastener.

3. Ring Gauge In contrast to plug gauges, ring gauges are used to measure external threads. They are designed similarly but feature an internal thread that matches the external dimensions of the fastener. Ring gauges guarantee that fasteners are manufactured within specific tolerances.

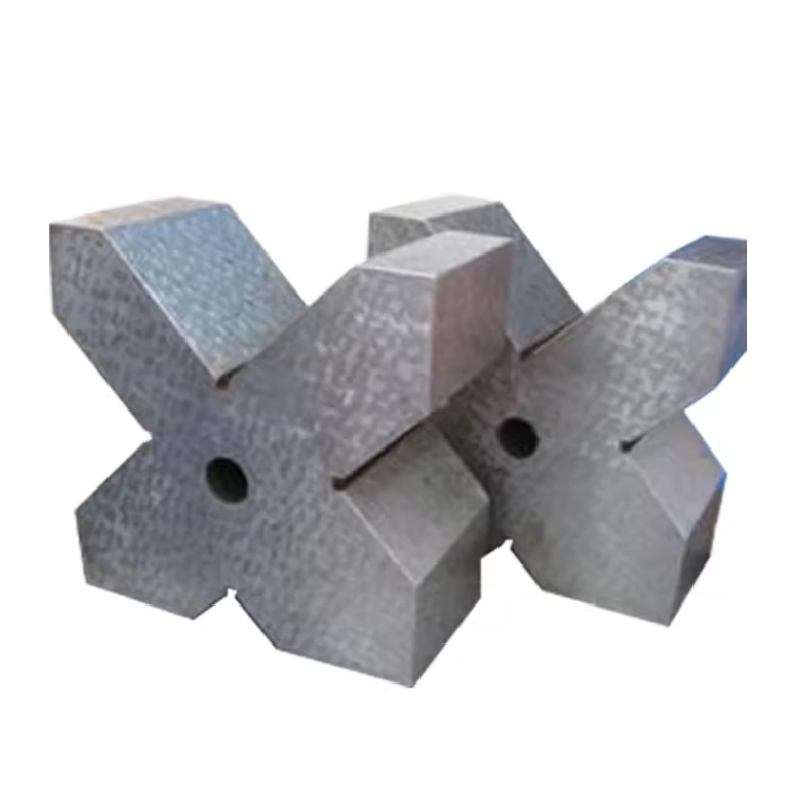

thread gauge tool

4. Thread Caliper A thread caliper combines the features of a caliper with those of a thread gauge. It allows users to measure the diameter and pitch simultaneously. This tool is especially useful for assessing custom or unique threads.

5. Thread Depth Gauge This specialized tool is used to measure the depth of threads, ensuring that they meet engineering standards. It's particularly important in applications where the depth of engagement is critical.

Applications of Thread Gauge Tools

Thread gauge tools find applications across various industries, including automotive, aerospace, construction, and general manufacturing. Here are a few critical applications

- Quality Control In manufacturing, ensuring that fasteners meet specified dimensions is vital for quality control. Thread gauges are essential tools in quality assurance processes, helping prevent defective products from reaching the market.

- Maintenance and Repair In automotive and engineering contexts, thread gauges aid technicians in determining the correct fastener sizes for repairs. This ensures that parts fit together securely, enhancing the overall safety and reliability of machinery.

- Custom Fabrication For manufacturers producing custom parts, thread gauges assist in designing and matching unique threads. This is crucial in niche applications where standard fasteners are not suitable.

Conclusion

In conclusion, thread gauge tools are indispensable instruments in the realm of precision engineering. They provide manufacturers, engineers, and technicians with the necessary measurements to ensure compatibility and quality in threaded components. With various types of thread gauges available, professionals can select the appropriate tool for their specific needs, ensuring that their products are made to the highest standards. As industries continue to advance, the role of thread gauge tools will only become more prominent, reaffirming their importance in maintaining safety and quality across the board.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS