ديسمبر . 28, 2024 09:36 Back to list

snap gauge

Understanding the Snap Gauge A Precision Tool in Measurement

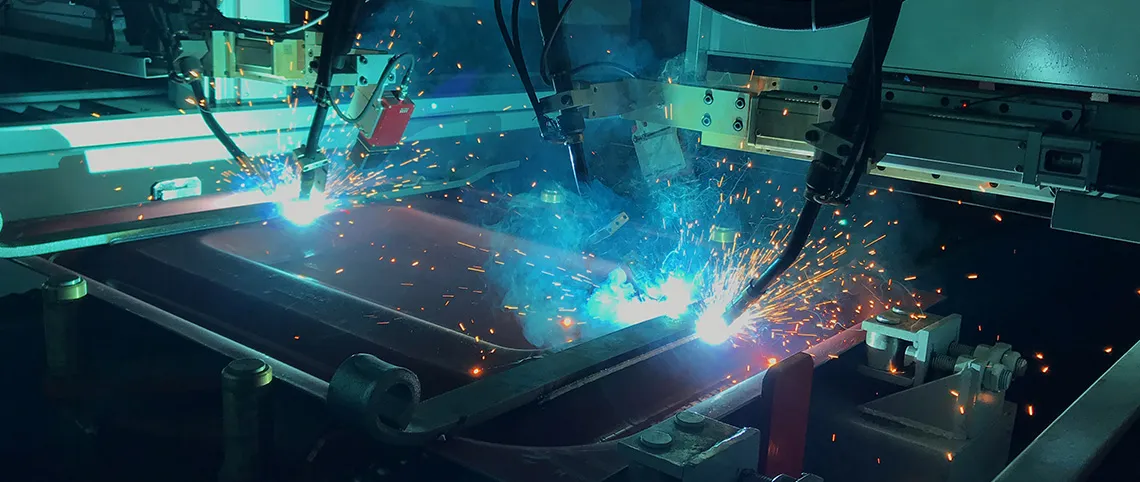

In the world of manufacturing and engineering, precision is key. One instrument that plays a critical role in achieving that precision is the snap gauge. Though not as widely recognized as calipers or micrometers, snap gauges offer unique advantages, particularly when it comes to measuring external dimensions quickly and efficiently. This article aims to delve into the functionality, types, and applications of snap gauges and why they are indispensable in various industries.

What is a Snap Gauge?

A snap gauge is a type of limit gauge designed to check the external dimensions of a workpiece. It typically consists of two fixed measuring surfaces and an adjustable surface that can be snapped into place against the workpiece. The primary purpose of a snap gauge is to provide a go/no-go measurement, meaning it checks if a part is within specified dimensional limits without providing a precise measurement of the dimension itself.

The simplicity of the design is one of its significant advantages. Operators can quickly determine whether a part meets the required specifications, which enhances productivity. Snap gauges can be made from various materials, including steel, carbide, and plastic, depending on the application's requirements.

Types of Snap Gauges

Snap gauges come in various forms, each tailored to specific measuring needs. The two primary types are

1. Go/No-Go Snap Gauges This is the most common type, where the gauge has two separate interfaces — one for the 'go' measurement and one for the 'no-go' measurement. If a part fits within the 'go' gauge but does not fit within the 'no-go' gauge, it is deemed acceptable. This type is favored in high-volume manufacturing settings where speed and simplicity are of the essence.

snap gauge

2. Variable Snap Gauges Unlike the go/no-go design, these gauges have adjustable measuring sections. They can be set to various dimensions, making them more versatile for varying specifications. Variable snap gauges are often used in situations where more than one dimension needs to be checked or where parts have varying size requirements.

Applications of Snap Gauges

Snap gauges find use in a multitude of industries - Automotive Manufacturing Used extensively in quality control to ensure that parts like pistons, cylinders, and other engine components meet the necessary tolerances. - Aerospace Industry Critical for measuring components where precision is non-negotiable and can impact safety and performance. - Machining and Fabrication Often used on the shop floor for quick checks of work-in-progress parts, helping to maintain tight tolerances throughout the manufacturing process. - Quality Assurance An essential tool in any QA department where rapid assessments of parts are required to keep production lines moving without delays.

Advantages of Using Snap Gauges

The benefits of snap gauges are numerous - Speed and Efficiency The primary advantage is the rapid measurement capability, allowing for swift quality checks without the need for extensive set-up time or complicated procedures. - Simplicity Snap gauges are easy to use. Even operators with minimal training can effectively use snap gauges, which reduces the potential for measurement errors. - Cost-effectiveness Generally, snap gauges are less expensive than other precision measuring instruments, making them an economical choice for manufacturers, especially those working with tight budgets.

Conclusion

In conclusion, while snap gauges may not be household names in the realm of measuring tools, their impact on the manufacturing and engineering sectors cannot be understated. Their ability to provide quick, reliable measurements makes them indispensable for quality assurance and efficiency on the production floor. As industries continue to emphasize precision and speed, the role of snap gauges will likely only increase, offering a robust solution to maintain the rigorous standards demanded by modern manufacturing processes. Investing in a quality snap gauge can pay dividends in both time savings and product quality, underscoring its value as a fundamental tool for engineers and manufacturers alike.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS