ديسمبر . 04, 2024 22:08 Back to list

no go ring gage

Understanding the No-Go Ring Gauge A Key Tool in Precision Engineering

In the world of precision engineering and manufacturing, the No-Go ring gauge serves as a critical tool for quality control and dimensional accuracy. This specialized gauge is part of a broader family of measurement devices that engineers, machinists, and quality control inspectors use to ensure that manufactured components meet their specified tolerances. Understanding its function, design, and application is essential for anyone involved in manufacturing processes.

What is a No-Go Ring Gauge?

A No-Go ring gauge is a cylindrical device that is used to check the size of a shaft or external diameter of a workpiece. The term No-Go indicates that the gauge should not fit onto the part being measured if the part is within the specified tolerance. Essentially, it is a form of limit gauge that helps ascertain whether a manufactured component has exceeded its maximum allowable dimensions.

How Does It Work?

The No-Go ring is designed to be slightly larger than the maximum allowable dimension specified for the part being measured. For a proper fit to be achieved, the part must be inserted into the gauge. If the part fits into the No-Go gauge, it indicates that the part exceeds its allowable size, and thus, it is considered out of tolerance. Conversely, if the part does not fit, it is within specifications. This binary assessment simplifies the inspection process and allows for quick determinations concerning the acceptability of components.

Construction and Calibration

no go ring gage

A No-Go ring gauge is typically made of high-quality tool steel or similar materials to ensure durability and long-term accuracy. The gauge is precision-engineered to ensure that it maintains its dimensional integrity over time, which is crucial in a manufacturing environment where tolerances can be very tight.

Regular calibration of these gauges is essential to maintain their accuracy. Calibration ensures that the gauge continues to provide reliable measurements and remains effective in quality control processes. Typically, manufacturers follow strict procedures to check and recalibrate these gauges periodically based on industry standards.

Application in Manufacturing

The No-Go ring gauge is particularly valuable in industries where precision is critical, such as automotive, aerospace, and medical device manufacturing. For instance, in the production of engine components, a No-Go gauge might be employed to verify whether a shaft adheres to the specified diameter requirements. If the shaft is too large, it may not fit properly in its intended assembly, potentially leading to mechanical failures.

The use of No-Go gauges also enhances overall efficiency in production by reducing the likelihood of defective parts proceeding through the manufacturing process. By catching out-of-tolerance components early, manufacturers can save on costs associated with rework and scrap.

Conclusion

In summary, the No-Go ring gauge is an essential instrument in precision engineering that plays a vital role in quality assurance. Its design allows for straightforward evaluation of manufactured components, ensuring they meet strict dimensional tolerances. By using this tool effectively, manufacturers can enhance production efficiency, reduce waste, and improve the overall quality of their products. Understanding and properly utilizing No-Go ring gauges is integral for anyone involved in the manufacturing process, reinforcing the importance of precision in modern engineering practices. As industries continue to evolve and demand higher standards, tools like the No-Go ring gauge will remain essential in the quest for quality and accuracy.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

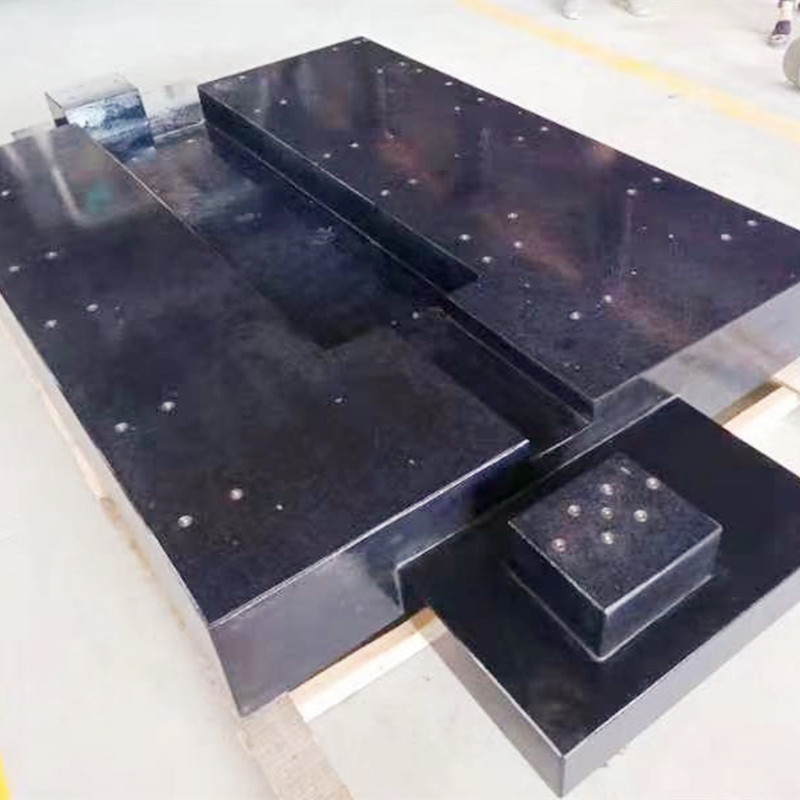

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS