ديسمبر . 23, 2024 23:45 Back to list

Precision Gauge Pin Set for Machinists and Toolmakers

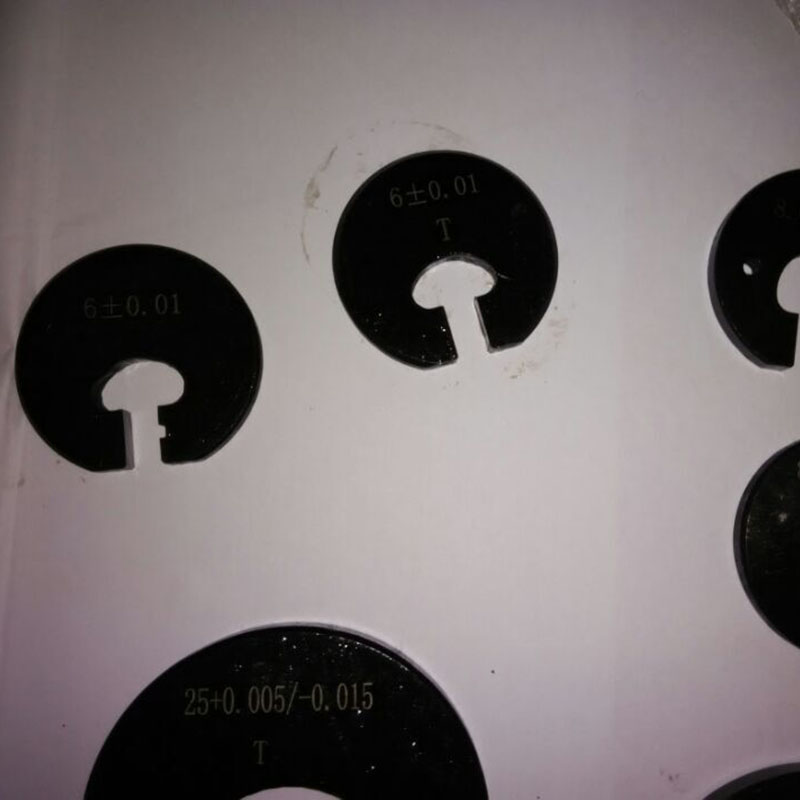

Understanding the Machinist Gauge Pin Set A Comprehensive Overview

In the world of machining and metalworking, precision is paramount. Machinists rely on a variety of tools to ensure their work meets strict specifications, and one essential tool in this toolkit is the gauge pin set. This article delves into the significance, applications, and benefits of machinist gauge pin sets, providing insights into why they are indispensable for accurate measurements and quality control in machining.

What is a Gauge Pin Set?

A gauge pin set is a collection of cylindrical pins, each precisely manufactured to specific diameters. These pins serve as a reference for measuring the dimensions of holes or slots and play a crucial role in assessing the accuracy of machined parts. Typically, gauge pins are made from high-speed steel or tool steel, which provides durability and resistance to wear. They are often ground to tight tolerances, ensuring that they can deliver the required precision for various applications.

Importance of Gauge Pins in Machining

The primary function of gauge pins is to enable machinists to check the size and roundness of holes, ensuring they conform to designated specifications. Incorrectly sized holes can lead to assembly issues, impacting the overall performance and safety of the machined part. Gauge pins can be used to verify the internal diameters of bores, the size of reamed holes, and in applications requiring a high level of precision.

Gauge pins come in various grades, including diameter grades and tolerance grades. For instance, some pins are intended for use in quality control, while others may be used as functional or assembly fits. Different applications dictate the need for various grades, making gauge pin sets versatile tools for machinists.

Applications in Industries

Gauge pin sets find extensive application across multiple industries, including automotive, aerospace, manufacturing, and tool making. In the automotive industry, for example, they may be used to check the dimensions of engine parts, ensuring they fit together correctly and function as intended. In aerospace, where precision is crucial for safety, gauge pins help maintain quality standards in critical components.

machinist gauge pin set

Moreover, in manufacturing environments where mass production occurs, maintaining consistency is vital. Gauge pins facilitate rapid measurement checks, allowing for immediate adjustments in production processes to adhere to tight tolerances.

Benefits of Using Machinist Gauge Pin Sets

1. Accuracy The foremost advantage of gauge pin sets is their accuracy. With manufacturing tolerances often measured in microns, these pins allow machinists to achieve the level of detail necessary for high-quality products.

2. Time Efficiency Implementing gauge pin checks in production processes can significantly reduce the time spent on inspection. By quickly verifying measurements with gauge pins, machinists can streamline their workflow and minimize downtime.

3. Cost-Effectiveness While the initial investment in a high-quality gauge pin set may seem significant, the long-term savings are substantial. By ensuring parts are manufactured to specification on the first attempt, companies can reduce waste and avoid costly rework.

4. Ease of Use Gauge pin sets are straightforward to use, requiring minimal training. Their simple cylindrical design allows machinists of all skill levels to incorporate them into their inspection routines seamlessly.

Conclusion

In conclusion, machinist gauge pin sets are vital tools in the precision machinery landscape. Their ability to provide accurate measurements, facilitate quality control, and enhance manufacturing efficiency makes them essential for a wide array of industries. By investing in a reliable gauge pin set, machinists not only ensure the accuracy of their work but also contribute to the overall quality of the products they produce. Ultimately, the gauge pin set exemplifies how a small tool can have a significant impact on the efficiency and success of machining operations.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS