أكتوبر . 08, 2024 05:32 Back to list

horizontal ball check valve

Horizontal Ball Check Valve An Overview

The horizontal ball check valve is an essential component in various fluid systems, designed to prevent backflow and ensure the one-way flow of liquids or gases. These valves are particularly popular in industries such as water treatment, oil and gas, and manufacturing because of their efficiency and reliability.

What Is a Horizontal Ball Check Valve?

A horizontal ball check valve uses a spherical ball to facilitate the flow of fluid. The valve is oriented horizontally, allowing gravity to assist in the sealing function. When fluid flows in the designated direction, the ball is pushed away from its seat, allowing movement through the valve. Conversely, when the flow reverses, the ball is forced back into its seat, effectively blocking any backward flow.

Key Features

One of the primary advantages of horizontal ball check valves is their simple yet effective design, which minimizes the risk of leaks

. These valves are constructed from durable materials such as stainless steel, brass, or plastic, which ensures long-term performance even under high pressure and temperature conditions. Additionally, their compact design allows for easy installation and integration into existing systems.horizontal ball check valve

Another notable feature is the valve's low-pressure drop characteristic. Unlike some other types of check valves, the horizontal ball check valve creates minimal resistance to the fluid flow, which is crucial in maintaining energy efficiency in fluid transport systems. This is particularly important in applications where pressure maintenance is critical, as it helps reduce pump strain and lowers operational costs.

Applications

Horizontal ball check valves are found in a wide array of applications. In water treatment facilities, they play a vital role in protecting pumps and other equipment from backflow, thereby ensuring system efficiency and safety. In the oil and gas industry, these valves help manage fluid transport in pipelines, maintaining the integrity of various systems and preventing costly leaks or overflows. Furthermore, they are also utilized in agricultural systems for irrigation, ensuring that water flows in the intended direction while preventing contamination.

Maintenance and Considerations

While horizontal ball check valves are known for their durability, regular maintenance is necessary to ensure optimal operation. Periodic inspections can help identify any signs of wear or damage that might impact performance. It is also essential to select the right size and material for specific applications to avoid any compatibility issues and ensure maximum efficiency.

In conclusion, the horizontal ball check valve serves as a critical component in various industries, providing reliable performance and preventing backflow in fluid systems. Their design, durability, and efficiency make them a preferred option for engineers and technicians looking to enhance system reliability. With proper maintenance and application, these valves can significantly improve operational efficiency and extend the lifespan of fluid transport systems.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

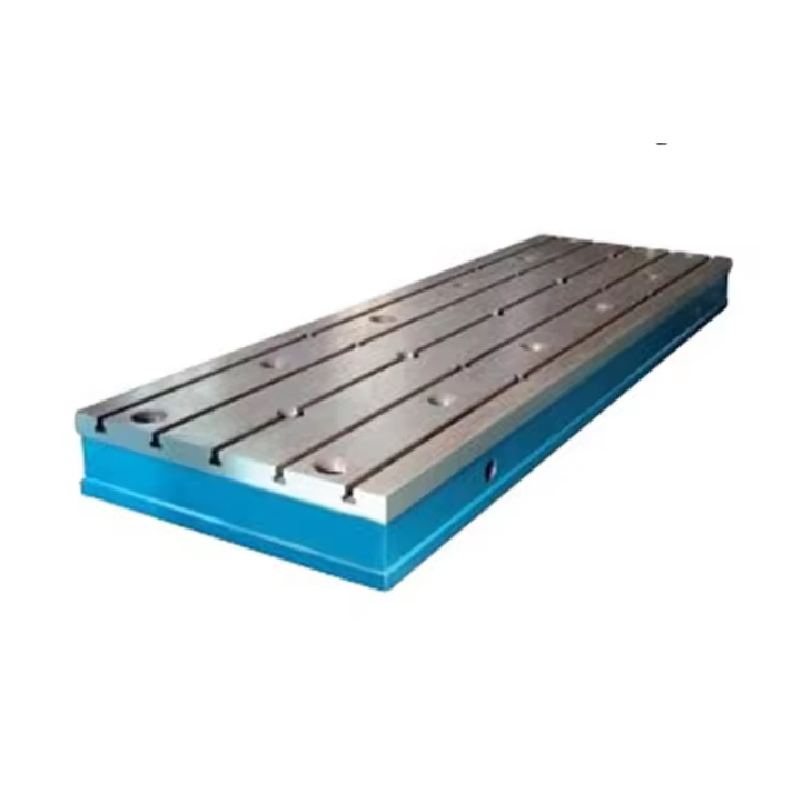

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS