أغسطس . 25, 2025 01:00 Back to list

Explore Guide Rail Types: Linear, Machine, & 15mm Precision Rails

Introduction to Precision Motion Systems

In the realm of modern industrial automation and precision manufacturing, the integrity and performance of motion systems are paramount. At the core of these systems lie various types of guide rails, critical components engineered to facilitate precise linear motion with minimal friction and maximum rigidity. Understanding the different guide rail types available is essential for engineers and decision-makers in selecting the optimal solution for their specific application requirements. These mechanical elements are designed to support and guide moving parts or workpieces along a predefined linear path, ensuring accuracy, repeatability, and structural stability in diverse operational environments. From heavy-duty machinery to ultra-precision instruments, the selection of an appropriate guide rail system directly impacts the efficiency, longevity, and overall performance of the equipment.

The complexity and sophistication of industrial applications demand guide rails that can withstand extreme conditions, deliver unparalleled accuracy, and offer extended service life. This comprehensive guide delves into the intricate world of guide rails, exploring their fundamental classifications, manufacturing processes, key technical specifications, and broad application spectrum. We will provide detailed insights to aid professionals in making informed decisions for their motion control challenges, ensuring their systems achieve peak performance and reliability.

Industry Trends and Evolutionary Demands

The industrial landscape is continuously evolving, driven by demands for higher productivity, increased automation, and enhanced precision. These trends significantly influence the development and adoption of various motion control components, including advanced guide rail systems. Key industry trends shaping the future of guide rail technology include:

- Miniaturization and Compact Design: As machines become smaller and more integrated, there's a growing need for compact yet high-performance guide rails that can fit into constrained spaces without compromising load capacity or precision.

- Higher Speed and Acceleration: Modern manufacturing processes require faster throughput, pushing the limits of guide rail dynamic capabilities to support higher speeds and rapid accelerations while maintaining smooth operation.

- Enhanced Precision and Repeatability: Industries like semiconductor manufacturing, medical device production, and advanced robotics demand sub-micron level precision, necessitating guide rails with exceptionally tight tolerances and minimal deflection.

- Durability and Harsh Environment Performance: Guide rails for sectors like petrochemical, metallurgy, and heavy machinery must withstand corrosive agents, extreme temperatures, and heavy shock loads, driving innovation in material science and surface treatments.

- Energy Efficiency: Reducing operational costs and environmental impact is a priority. Guide rail designs that minimize friction and enhance efficiency contribute to overall energy savings in industrial systems.

- Integration with Smart Systems: The rise of Industry 4.0 and IoT leads to guide rails being integrated with sensors for condition monitoring, predictive maintenance, and real-time performance optimization.

These evolving demands necessitate continuous innovation in the design, materials, and manufacturing processes of all guide rail types, ensuring they remain at the forefront of motion control technology.

Understanding the Diverse Guide Rail Types

The selection of appropriate guide rail types is pivotal for the success of any linear motion application. Each type offers distinct advantages tailored to specific operational requirements concerning load capacity, precision, speed, and environmental conditions. The primary categories of linear guide rail systems include:

- Profiled Rail Linear Guides (Ball or Roller): These are among the most common and versatile linear guide rail types. They feature a precision-ground rail with a specific cross-sectional profile, such as a square or circular shape, and a carriage that moves along it. The carriage contains recirculating balls or rollers that provide low-friction, high-precision motion. Ball-type guides offer excellent speed and accuracy, while roller-type guides provide superior rigidity and load capacity, particularly in heavy-duty applications. Their robust design makes them suitable for machine tools, automation, and robotics.

- Cylindrical Linear Guides: Also known as shaft guides, these consist of hardened and ground steel shafts with linear ball bearings or bushings. They are often simpler in design and cost-effective for applications requiring moderate precision and load capacity. Common in packaging machinery, woodworking equipment, and general automation.

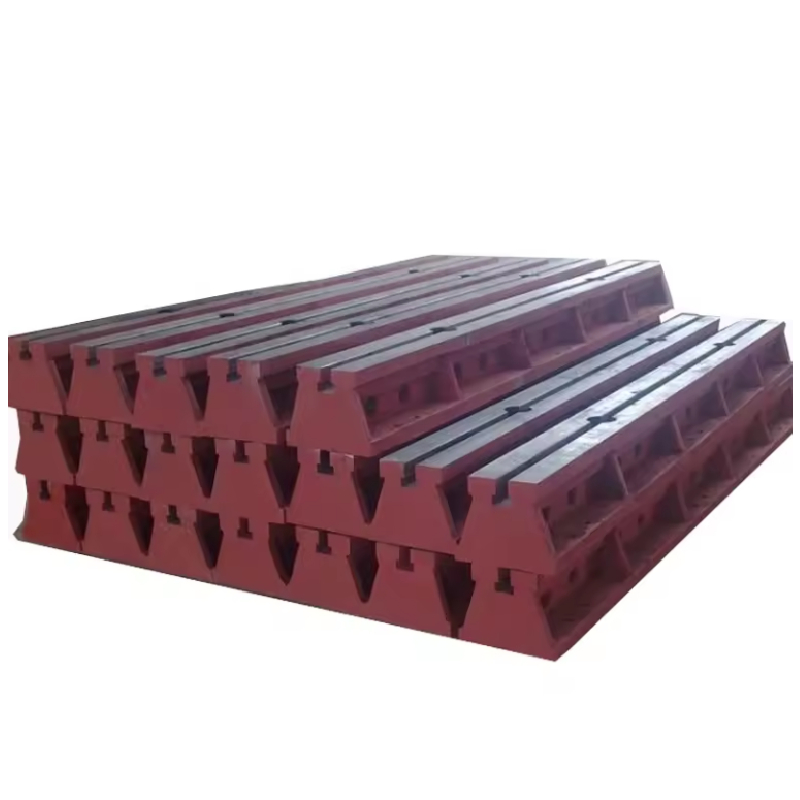

- Dovetail Slide Guides: These guides utilize a sliding friction mechanism, often made of cast iron or bronze, where one component slides within a mating dovetail groove. While providing high rigidity and damping, they typically exhibit higher friction than rolling element guides and are generally used for slower, heavier loads where vibration damping is critical, such as in grinding machines.

- Hydrostatic and Aerostatic Guides: These advanced machine guide rails utilize a thin film of pressurized fluid (oil for hydrostatic, air for aerostatic) to create a frictionless bearing surface between the guide and the carriage. They offer ultra-high precision, exceptional stiffness, and virtually no wear, making them ideal for metrology, optical systems, and semiconductor manufacturing, where absolute accuracy is paramount.

- Crossed Roller Guides: Comprising two V-grooved rails and a cage containing rollers arranged in a crossed pattern, these guides offer very high rigidity, precision, and low friction over a compact stroke. They are frequently used in precision measurement equipment and cleanroom environments.

Each type presents a unique combination of performance characteristics. For instance, a linear guide rail bearing system integrated into a profiled rail can handle significant radial and axial loads, making it a robust choice for complex industrial tasks.

Key Performance Parameters Comparison of Linear Guide Rail Types

| Feature/Type | Profiled Rail (Ball) | Profiled Rail (Roller) | Cylindrical Rail | Hydrostatic/Aerostatic |

|---|---|---|---|---|

| Precision | High | Very High | Medium to High | Ultra-High |

| Load Capacity | High | Very High (Heavier Loads) | Medium | High (Stiffness) |

| Speed Capability | Very High | High | Medium to High | Medium |

| Friction | Very Low | Very Low | Low | Virtually Zero |

| Stiffness/Rigidity | High | Very High | Medium | Exceptional |

| Cost | Medium to High | High | Low to Medium | Very High |

The Advanced Manufacturing Process of Guide Rails

The production of high-performance guide rail types is a meticulous process involving advanced materials, precision machining, and stringent quality control. Each step is critical in ensuring the final product meets the demanding specifications required for industrial applications. Here’s a detailed look at the typical manufacturing process:

Process Flow Overview:

-

1. Material Selection & Preparation:

High-quality alloy steels, such as SAE 52100 (GCr15 equivalent for ball bearings) or specialized stainless steels (e.g., SUS440C for corrosion resistance), are chosen for their hardness, wear resistance, and fatigue strength. Raw material undergoes initial inspection for composition and structural integrity. For certain applications, aluminum alloys with specific surface treatments are used for lightweight solutions.

-

2. Rough Machining (Cutting & Turning):

The selected material billets are cut to length and undergo initial turning or milling operations to achieve a near-net shape, removing excess material and preparing the surface for subsequent treatments. This stage focuses on efficiency while maintaining basic dimensional accuracy.

-

3. Heat Treatment (Hardening & Tempering):

The guide rail blanks are subjected to specialized heat treatment processes, typically hardening (quenching) followed by tempering. This significantly increases the material's hardness, wear resistance, and load-bearing capacity, achieving core hardness and surface hardness specifications crucial for service life. For example, bearing steel guide rails are often heat-treated to HRC 58-62.

-

4. Precision Grinding & Finishing:

This is the most critical stage for achieving the required geometric accuracy and surface finish. CNC grinding machines are utilized to precisely machine the guide rail surfaces, especially the raceways, to achieve strict tolerances for straightness, parallelism, and surface roughness. This stage directly influences the precision class and smoothness of linear motion. Advanced grinding techniques ensure minimal deviation and superior surface integrity.

-

5. Surface Treatment (Optional but Common):

Depending on the application, guide rails may undergo further surface treatments. These include black oxidization for corrosion resistance, hard chrome plating for enhanced wear resistance and hardness, or specialized coatings like thin-dense chrome (TDC) or proprietary ceramic coatings for extreme environments (e.g., petrochemical and marine applications, providing excellent corrosion resistance against saltwater and various chemicals).

-

6. Assembly (for integrated systems) & Lubrication:

For complete linear motion systems, the finished guide rails are assembled with carriages, ball bearings, or rollers. Pre-lubrication with high-performance grease or oil is applied to ensure smooth initial operation and extend service life. Advanced sealing mechanisms are also integrated to protect internal components from contaminants.

-

7. Final Inspection & Testing:

Each guide rail undergoes rigorous final inspection and testing according to international standards such as ISO 12090-1 (for linear rolling bearings), ANSI/ABMA standards, and proprietary internal quality standards. This includes dimensional verification, hardness testing, straightness and parallelism checks, surface roughness measurement, and functional testing under simulated load conditions to confirm precision, rigidity, and smooth operation. The typical service life of high-quality guide rails can exceed 10,000 km under rated load and proper maintenance.

-

8. Packaging & Shipping:

Finished guide rails are carefully packaged to prevent damage during transit, often using anti-corrosion materials and robust crating, ready for delivery to target industries such as machine tools, automation, robotics, medical devices, semiconductor manufacturing, and specialized sectors like petrochemical, metallurgy, and water supply & drainage, where energy saving and corrosion resistance are key advantages.

Figure 1: High-precision linear guide rail components undergoing final inspection.

Technical Specifications and Product Parameters

Understanding the technical specifications of guide rail types is crucial for engineers to select the correct component for optimal system performance. These parameters define the rail's capability, precision, and longevity. Key technical parameters include dynamic load rating, static load rating, moment loads, precision grade, parallelism, straightness, and material composition.

Example: Typical Specifications for a 15mm Linear Guide Rail (Profiled Rail Type)

Focusing on a common dimension, the 15mm linear guide rail is a popular choice for medium-load applications requiring high precision. Below are typical specifications you might find:

| Parameter | Value/Range | Unit/Description |

|---|---|---|

| Nominal Rail Width (W) | 15 | mm |

| Dynamic Load Rating (C) | 7,500 - 10,000 | N (Newtons) |

| Static Load Rating (C₀) | 12,000 - 15,000 | N (Newtons) |

| Precision Grade | H (High), P (Precision) | ISO Standard |

| Maximum Speed | 3 - 5 | m/s |

| Parallelism (block to rail) | ±0.010 - ±0.020 | mm / 1000mm length |

| Operating Temperature Range | -20 to +80 | °C |

| Material | Alloy Steel (e.g., S55C, GCr15), Stainless Steel | Hardened & Ground |

These specifications highlight the capabilities of a typical linear guide rail bearing system. Dynamic load rating (C) represents the load at which 90% of a group of identical guide rails will achieve a service life of 50,000 meters, while static load rating (C₀) is the maximum permissible static load without causing permanent deformation. Moment load ratings (M_r, M_p, M_y) are also critical for applications involving cantilevered or eccentric loads. Precision grades, from Normal (N) to Super Precision (SP), define the allowable positional accuracy and running parallelism, directly impacting the final product quality and consistency in manufacturing processes.

Versatile Application Scenarios and Technical Advantages

The extensive range of guide rail types ensures their applicability across virtually every industrial sector requiring precise linear motion. Their technical advantages are the cornerstone of efficiency and reliability in modern machinery. Key application scenarios and inherent benefits include:

- Machine Tools: In CNC machining centers, lathes, and milling machines, high-precision machine guide rails (often profiled roller type) ensure the extreme accuracy of tool and workpiece positioning, leading to superior surface finishes and tight dimensional tolerances. The high rigidity minimizes vibration, contributing to longer tool life and consistent part quality.

- Industrial Automation & Robotics: From pick-and-place robots to automated assembly lines, linear guide rails provide the smooth, high-speed, and repeatable motion required for efficient production. Their low friction contributes to energy saving by reducing the power needed to drive the motion.

- Semiconductor Manufacturing: Ultra-precision guide rails, including hydrostatic and aerostatic types, are vital for wafer processing, inspection, and packaging equipment. They offer sub-micron positioning accuracy, crucial for micro-scale manufacturing, and ensure minimal contamination due to their non-contact nature.

- Medical Devices: In MRI machines, patient positioning systems, and laboratory automation, guide rails provide quiet, smooth, and precise motion, often in compact designs. Stainless steel versions offer excellent corrosion resistance for sterile environments.

- Packaging Machinery: High-speed packaging lines benefit from the durability and rapid motion capabilities of linear guide rails, ensuring quick and reliable product handling.

- Specialized Industries (Petrochemical, Metallurgy, Water Treatment): For applications in corrosive or harsh environments, guide rails made from specialized materials like stainless steel (e.g., SUS304, SUS316) or those with advanced corrosion resistance coatings are indispensable. In water supply & drainage systems, for example, corrosion resistance ensures long-term operational integrity and significantly reduces maintenance costs.

The inherent technical advantages across all guide rail types – including high precision, superior rigidity, impressive load capacities, smooth and low-friction motion, and extended service life – make them foundational elements for achieving operational excellence and energy efficiency in a multitude of industrial processes. The ability to tailor materials and coatings also enhances their performance in specific, challenging environments.

Figure 2: Linear motion systems featuring robust guide rails in an automated assembly line.

Vendor Comparison and Customized Solutions

Choosing the right vendor for guide rail types is as critical as selecting the right product. B2B decision-makers must evaluate suppliers based on expertise, product quality, customization capabilities, and post-sales support. A reliable partner offers not just components but integrated solutions that enhance system performance and longevity.

Key Criteria for Vendor Evaluation:

- Product Quality & Certifications: Assess adherence to international standards (e.g., ISO 9001 for quality management, CE for product safety) and material certifications. Look for evidence of rigorous testing and quality control protocols throughout the manufacturing process.

- Technical Expertise & R&D: A reputable vendor will possess deep engineering knowledge, offering design assistance and application-specific recommendations. Their commitment to research and development ensures access to the latest advancements in linear guide rail types.

- Customization Capabilities: For unique applications, standard components may not suffice. The ability to provide customized lengths, drilling patterns, specialized coatings (e.g., for corrosion resistance or cleanroom environments), or specific precision grades is a significant advantage.

- Lead Time & Logistics: Timely delivery is crucial for project schedules. Evaluate a vendor's supply chain efficiency, inventory management, and global distribution network.

- Customer Support & After-Sales Service: Responsive technical support, comprehensive warranties, and readily available spare parts contribute significantly to overall customer satisfaction and operational continuity.

Our company, with decades of expertise in precision engineering, prides itself on delivering high-quality machine guide rails that meet the most stringent industry standards. We partner with leading industrial manufacturers globally, providing not just components but comprehensive motion solutions. Our ISO 9001 certification and adherence to various industry-specific standards underscore our commitment to excellence.

Tailored Solutions for Unique Challenges:

We understand that off-the-shelf solutions don't always meet every intricate requirement. Our specialized engineering team works closely with clients to develop customized guide rail types that precisely match their application's demands. This includes:

- Material Optimization: Selecting specific alloys for extreme temperatures, high loads, or superior corrosion resistance (e.g., for petrochemical or marine applications).

- Surface Engineering: Applying specialized coatings (DLC, hard chrome, ceramic) to enhance wear resistance, reduce friction, or improve performance in vacuum/cleanroom environments.

- Dimensional Modifications: Custom lengths, mounting hole patterns, and non-standard cross-sections to integrate seamlessly into existing designs or optimize new ones.

- Integrated Sensor Solutions: Incorporating position sensors or condition monitoring features for advanced diagnostic capabilities and predictive maintenance within the linear guide rail bearing system.

This collaborative approach ensures that our clients receive a solution perfectly engineered for their operational environment, delivering optimal performance and cost-efficiency.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits and reliability of properly selected guide rail types. Our extensive experience has led to successful deployments across diverse industries, showcasing enhanced performance and significant operational improvements for our clients.

Case Study 1: High-Speed Automated Packaging Line

A leading food packaging company faced challenges with inconsistent product positioning and frequent maintenance due to wear in their existing linear motion systems. We recommended upgrading their critical handling stations with our high-speed, profiled linear guide rail types, specifically a 25mm roller-type guide rail system known for its superior rigidity and dynamic load capacity. The new system significantly reduced vibration, improved positioning accuracy by 30%, and increased line speed by 15%, leading to a substantial boost in throughput and a 40% reduction in unplanned downtime. Customer feedback highlighted the enhanced reliability and precision, directly impacting their bottom line.

Case Study 2: Precision CNC Grinding Machine

A manufacturer of high-precision metal components required extremely stiff and accurate linear motion for their new generation of CNC grinding machines. Their existing guides exhibited unacceptable deflection under heavy grinding forces. We engineered a custom solution utilizing heavy-duty profiled machine guide rails with preloaded carriages, ensuring maximum rigidity and minimal deflection. This allowed for finer grinding passes and superior surface finishes. The solution incorporated advanced sealing to protect the linear guide rail bearing components from abrasive grinding dust, extending the service life dramatically. The client reported an increase in part quality consistency and a notable reduction in post-grinding rework.

Case Study 3: Offshore Oil & Gas Equipment

Operating in harsh marine environments, an offshore equipment provider needed guide rails for a critical subsea inspection system that could withstand constant saltwater exposure and high pressures. Standard guide rails corroded rapidly. Our solution involved custom-fabricated guide rail types from specialized super duplex stainless steel, enhanced with a multi-layer ceramic-polymer coating. This bespoke solution provided unprecedented corrosion resistance and maintained operational integrity for over five years in a highly aggressive environment, far exceeding the performance of previous systems and demonstrating a significant return on investment.

Commitment to Trustworthiness: FAQs, Lead Times, Warranty & Support

Building trust is paramount in B2B relationships. We are committed to transparency and providing exceptional support throughout the entire lifecycle of our guide rail types. Our commitment extends from initial consultation to long-term after-sales service.

Frequently Asked Questions (FAQs)

A1: Selection depends on several factors, including load capacity (dynamic and static), required precision, speed, acceleration, stroke length, operating environment (temperature, contaminants, corrosion), and budget. Our engineering team can provide a detailed analysis and recommend the most suitable linear guide rail types based on your specific requirements.

A2: Regular lubrication is crucial to achieve the rated service life and ensure smooth operation. The frequency and type of lubricant depend on the application, operating speed, and environment. We provide detailed maintenance guidelines for all our machine guide rails, including recommendations for automatic lubrication systems.

A3: Yes, we offer specialized guide rail types made from corrosion-resistant materials (e.g., stainless steel) and with advanced surface coatings to withstand extreme temperatures, chemicals, and corrosive agents. We also provide sealing solutions for dusty or wet environments.

A4: Under proper selection, installation, and regular maintenance, our high-quality guide rails are designed for a service life exceeding 10,000 km, often extending to 50,000 km or more, depending on the load and operating conditions. Our products are engineered for long-term reliability.

Lead Time & Fulfillment

We maintain an optimized production schedule and inventory of standard guide rail types to ensure rapid fulfillment. Typical lead times for standard products range from 2-4 weeks. For custom solutions or large-volume orders, lead times are provided on a project-specific basis, with our team actively communicating progress at every stage. Expedited shipping options are available upon request.

Warranty Commitments

All our linear guide rail bearing products come with a comprehensive 12-month warranty against manufacturing defects from the date of purchase. This commitment reflects our confidence in the quality and durability of our engineering. Extended warranty options are also available for specific projects or high-demand applications, providing an extra layer of assurance for your investment.

Dedicated Customer Support

Our commitment to customer satisfaction extends far beyond the sale. Our dedicated technical support team, comprising experienced engineers, is available to assist with product selection, installation guidance, troubleshooting, and maintenance inquiries. We offer multi-channel support via phone, email, and a comprehensive online resource center, ensuring you have access to the expertise you need, when you need it. We strive to provide prompt, effective solutions to keep your operations running smoothly.

Figure 3: Quality assurance testing in progress for various guide rail types.

Conclusion

The array of guide rail types available today represents the pinnacle of precision engineering, each designed to meet specific demands of modern industrial motion control. From the robust roller-type linear guides for heavy machinery to the ultra-precise hydrostatic systems for semiconductor manufacturing, the right choice profoundly impacts system performance, reliability, and cost-efficiency. As industries continue to advance towards higher automation, greater speed, and more stringent precision, the evolution of guide rail technology will remain a critical enabler. Partnering with a knowledgeable and experienced vendor, capable of offering both standard and customized solutions, ensures that your linear motion systems are optimized for current and future challenges, driving innovation and maintaining a competitive edge.

References

- ISO 12090-1:2017. Linear rolling bearings — Part 1: Boundary dimensions and tolerances for linear ball bearings. International Organization for Standardization.

- SKF. (2018). _SKF Linear Motion Product Catalogue_.

- THK Co., Ltd. (2020). _THK General Catalogue for Linear Motion Products_.

- Hiwin Corporation. (2019). _Linear Guideway Catalogue_.

- Bosch Rexroth. (2021). _Linear Motion Technology Handbook_.

- Slocum, A. (1992). _Precision Machine Design_. Prentice Hall.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS