مايو . 12, 2025 17:24 الرجوع للقائمة

Boosting Workshop Productivity Using Granite Blocks

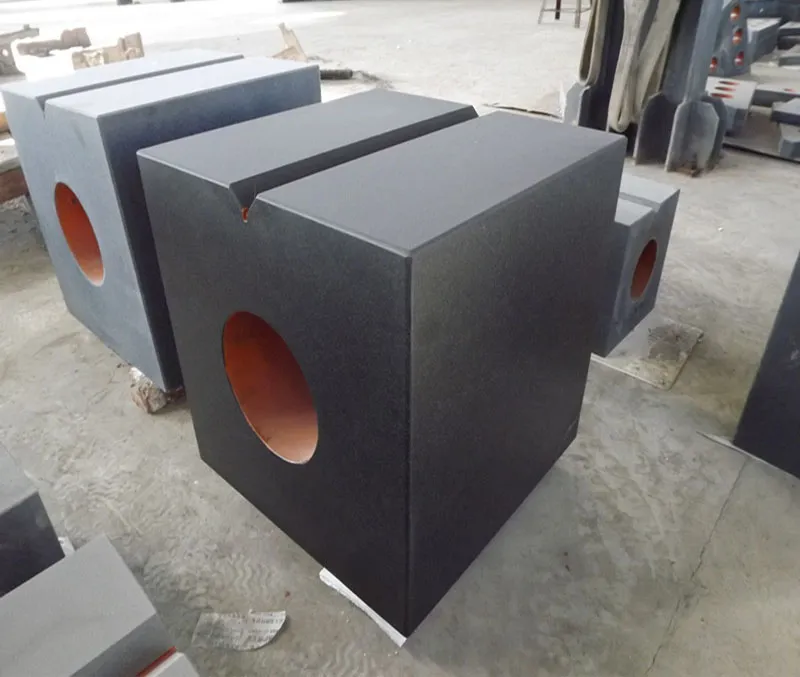

In any workshop, the tools and materials used can significantly influence productivity and precision. Among these, the block of granite stands out as an essential component for various applications, particularly in the realm of machining and fabrication. Granite is known for its durability, stability, and resistance to deformation, making it an ideal material for creating surfaces that require high precision. The use of a flat granite block as a reference surface ensures that measurements and alignments are accurate, which is crucial in any manufacturing process.

When workers utilize granite stone blocks, they benefit from a stable and reliable platform that can withstand heavy loads and resist wear over time. This stability is particularly important when performing tasks that require meticulous attention to detail, such as welding and machining. The flatness of large granite blocks contributes to the overall quality of the work being done, as any deviation from a true flat surface can lead to errors and rework, ultimately affecting productivity. By incorporating block of granite into the workshop, businesses can enhance their operational efficiency and reduce the likelihood of costly mistakes.

Moreover, the use of granite in workshops is not just about functionality; it also reflects a commitment to quality. When clients see that a workshop employs high-quality materials like granite stone blocks, it instills confidence in the craftsmanship and precision of the work produced. This perception can lead to increased customer satisfaction and repeat business, further boosting productivity and profitability in the long run.

Enhancing Measurement Accuracy with Flat Granite Block

One of the primary uses of a flat granite block is in the realm of measurement and inspection. In workshops where precision is paramount, having a reliable reference point is essential. The flatness of granite makes it an excellent choice for this purpose, as it provides a stable surface against which other components can be measured. This is particularly important in industries where tolerances are tight, such as aerospace, automotive, and electronics manufacturing.

When using a flat granite block, workers can perform various measurement tasks with confidence. For instance, when checking the flatness of machined parts or ensuring that components are aligned correctly, the granite block acts as a baseline. This capability allows for quick adjustments and corrections, thereby minimizing downtime and enhancing overall productivity. Additionally, the durability of granite ensures that the measuring surface remains intact over time, reducing the need for frequent replacements or repairs.

Furthermore, incorporating a flat granite block into the workflow can streamline processes. Instead of relying on less stable materials or makeshift surfaces, workers can utilize this reliable tool to facilitate efficient measurements. This not only saves time but also reduces the potential for human error, leading to higher quality outputs. In a competitive market, being able to deliver precise and accurate work consistently can set a workshop apart from its competitors, making the investment in flat granite blocks worthwhile for any business looking to enhance productivity.

Granite Stone Blocks: A Versatile Tool for Various Applications

The versatility of granite stone blocks extends beyond mere measurement; they serve multiple functions in a workshop environment. From providing a stable surface for machining to acting as a base for welding, these blocks are invaluable assets in any industrial setting. Their ability to absorb vibrations is particularly beneficial when performing operations that require high precision, such as CNC machining or grinding. By minimizing vibrations, granite stone blocks help maintain the integrity of the workpiece, ensuring that the final product meets stringent quality standards.

In addition to their functional benefits, large granite blocks can be used creatively in workshops. For example, they can serve as makeshift tables for assembling components or as support structures for heavy machinery. The robustness of granite means it can withstand the rigors of daily use without succumbing to wear and tear. This versatility makes granite stone blocks a smart investment for workshops that seek to optimize their space and resources effectively.

Moreover, the aesthetic appeal of granite cannot be overlooked. Its natural beauty adds a touch of elegance to any workspace, creating an environment that is both functional and visually pleasing. When employees work in a well-organized and attractive setting, it can lead to increased morale and motivation, further enhancing productivity. By integrating granite stone blocks into the workshop, businesses not only improve their operational capabilities but also foster a positive work atmosphere that encourages efficiency and innovation.

The Role of Large Granite Blocks in Heavy-Duty Applications

In heavy-duty applications, large granite blocks play a crucial role in providing stability and support. These blocks are particularly useful in industries where substantial weight and pressure are involved, such as manufacturing and construction. Their inherent strength allows them to bear significant loads without compromising their structural integrity, making them ideal for use as bases for heavy machinery or as supports for large assemblies.

The durability of large granite blocks means they can withstand harsh conditions, including exposure to chemicals, extreme temperatures, and mechanical stress. This resilience makes them a preferred choice for workshops that require materials capable of enduring tough environments. Additionally, the non-porous nature of granite ensures that it does not absorb liquids, which can lead to contamination or damage over time. This feature is particularly important in workshops that deal with various fluids and materials, as it helps maintain a clean and safe working environment.

Furthermore, the use of large granite blocks in conjunction with other tools, such as a welding inspection ruler, enhances overall productivity. The combination of a stable granite surface and precise measurement tools allows workers to perform tasks with greater accuracy and confidence. This synergy between materials and tools is essential for achieving high-quality results in any workshop setting. By investing in large granite blocks, businesses can ensure that they have the right foundation for their operations, leading to improved efficiency and output.

FAQs: Understanding Granite Blocks and Their Applications

What are the benefits of using a block of granite in a workshop?

A block of granite provides a stable, durable surface for precise measurements and machining, enhancing overall productivity and reducing errors.

How does a flat granite block improve measurement accuracy?

A flat granite block serves as a reliable reference surface, allowing for accurate measurements and alignments, which is crucial in high-precision industries.

Can granite stone blocks be used for heavy-duty applications?

Yes, large granite blocks are ideal for heavy-duty applications due to their strength and ability to withstand significant loads without losing integrity.

How do granite blocks contribute to workshop aesthetics?

Granite's natural beauty adds an elegant touch to workshop environments, creating a visually pleasing workspace that can boost employee morale.

What is the role of a welding inspection ruler with granite blocks?

A welding inspection ruler, when used with granite blocks, enhances measurement accuracy and helps ensure that welds meet quality standards, improving overall project outcomes.

Discover the benefits of incorporating granite stone blocks and flat granite blocks into your operations. Visit our website to explore our range of high-quality granite products and elevate your workshop's productivity today!

-

Thread Plug Gauge Our Promise of Measurement ExcellenceأخبارAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyأخبارAug.22,2025

-

Check Valve Types for High Rise BuildingsأخبارAug.22,2025

-

Water Control Valve for Irrigation SystemsأخبارAug.22,2025

-

Gate Valve with Soft Seal TechnologyأخبارAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsأخبارAug.22,2025

منتجات ذات صله