نوفمبر . 10, 2024 07:26 Back to list

Cost Analysis for 250mm Butterfly Valves in the Market Today

Understanding the Price Factors of a 250mm Butterfly Valve

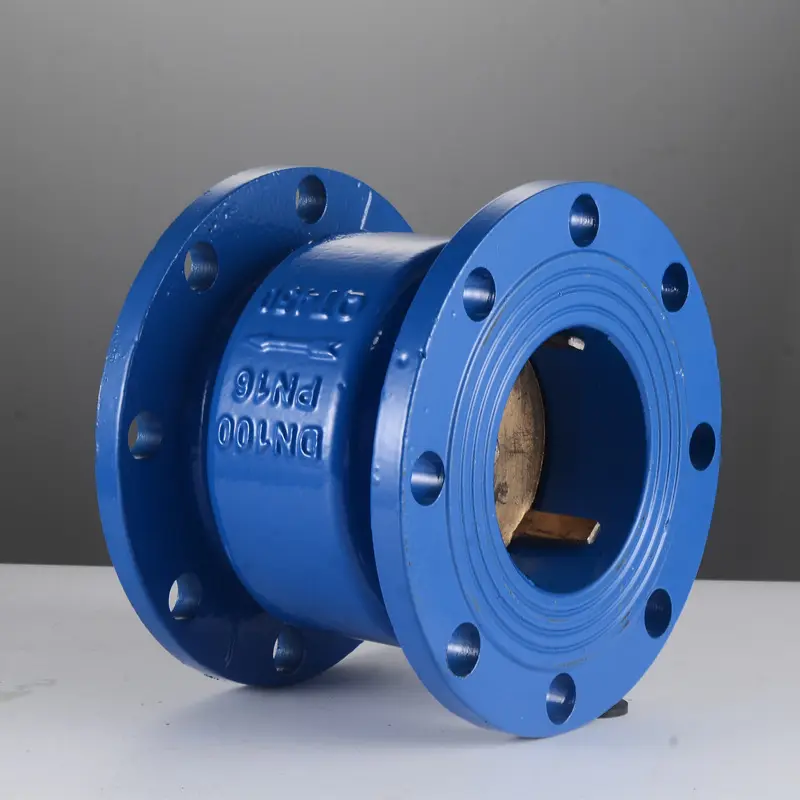

When selecting a butterfly valve for your application, understanding the pricing factors is essential. The butterfly valve is a widely used component in pipelines and systems for controlling the flow of fluids. A 250mm butterfly valve, specifically, is a size that efficiently regulates flow in various industrial settings, including water treatment, chemical processing, and HVAC systems. This article will delve into the components that influence the price of a 250mm butterfly valve and provide insights into why investing in quality valves is crucial.

Basic Components Affecting Price

1. Material The material from which the valve is constructed significantly influences its price. Common materials include cast iron, stainless steel, PVC, and carbon steel. Cast iron valves tend to be more affordable but may not be suitable for aggressive environments. Stainless steel offers excellent corrosion resistance, making it a more expensive yet durable option, particularly for chemical applications. The choice of material will be dictated by the intended application and fluid characteristics.

2. Type of Valve Butterfly valves are available in various designs, such as resilient seated, metal seated, and high-performance designs. Each type has different manufacturing processes and material specifications, which can lead to variances in price. For instance, high-performance butterfly valves, which offer enhanced sealing and operational reliability, often come at a premium due to their advanced design and materials.

3. Size and Specifications The size of the valve, denoted here as 250mm, directly affects its cost. Larger valves not only require more raw materials but also involve more complicated manufacturing processes. Additionally, the pressure rating and temperature specifications can influence pricing. Higher ratings typically mean that the valve needs to withstand more pressure, necessitating the use of more robust materials and precise engineering.

4. Actuation Method Butterfly valves can be operated manually or automatically. Automated valves, which may incorporate electric or pneumatic actuators, will incur additional costs due to the complexity of the actuator assembly and control mechanisms. Manual valves, on the other hand, usually come at a lower price point but may require more labor to handle during operation.

250mm butterfly valve price

5. Brand and Manufacturer The reputation of the brand and the manufacturer also plays a vital role in determining price. Well-established brands often charge more due to their reliability, warranty terms, and customer support. However, opting for lesser-known manufacturers can be cost-effective, but it may come at the risk of quality and support.

Market Trends

The price of butterfly valves, including the 250mm variety, can fluctuate based on market conditions. Economic factors such as raw material costs, supply chain disruptions, and demand for industrial components can impact pricing. Additionally, global trends in sustainability and environmental regulations may push manufacturers to innovate or to utilize more sustainable materials, potentially influencing pricing.

Cost-Benefit Analysis

When considering the purchase of a 250mm butterfly valve, it is essential to conduct a thorough cost-benefit analysis. While purchasing a low-cost valve may seem attractive initially, it's vital to assess the long-term implications. Poor quality valves can lead to frequent repairs, increased downtime, and ultimately higher operational costs. Investing in quality valves from reputable manufacturers can reduce maintenance costs and extend the lifespan of the valve.

Conclusion

In conclusion, the price of a 250mm butterfly valve is influenced by various factors, including material, type, size, actuation method, and brand reputation. Understanding these elements allows buyers to make informed decisions tailored to their specific needs. While price is undoubtedly a critical consideration, prioritizing quality and reliability can lead to significant long-term savings and efficiency in operations. As industries continue to evolve, ensuring that you have the right valve is crucial for meeting operational demands and maintaining system integrity.

-

Surface Plate Maintenance Best Practices for LongevityNewsJun.27,2025

-

Historical Evolution of Iron Surface Plates in Industrial MetrologyNewsJun.27,2025

-

Cast Iron Y Strainer Safety StandardsNewsJun.27,2025

-

Blockchain Verification for Gauge Tool Certification IntegrityNewsJun.27,2025

-

Advantages of Triple Offset Butterfly Valve Types in High-Pressure SystemsNewsJun.27,2025

-

Wear Resistance Strategies for Trapezoidal ThreadsNewsJun.26,2025

Related PRODUCTS