ታኅሣ . 19, 2024 11:03 Back to list

Precision Measurement Tools for Dial Bore Gauging Applications in Engineering and Manufacturing

Understanding the Standard Dial Bore Gauge An Essential Tool for Precision Measurement

In the realm of manufacturing and engineering, precision is paramount. One of the key instruments that facilitate accurate measurements within cylindrical objects — such as holes and bores — is the standard dial bore gauge. This article delves into the features, applications, and advantages of using a dial bore gauge in various industries.

What is a Dial Bore Gauge?

A dial bore gauge is a specialized measuring instrument used to assess the internal diameter of a cylindrical workpiece. Unlike traditional calipers, which measure external dimensions, dial bore gauges are designed to fit into the bore of the part to deliver precise readings. This instrument typically consists of a dial indicator mounted on a shaft, equipped with internal measuring arms that can expand and contract to measure different diameters.

Structure and Components

The basic structure of a standard dial bore gauge includes the following components

1. Dial Indicator The dial is the most crucial part, displaying measurement readings in either metric or imperial units. The needle on the dial moves in response to changes in bore diameter.

2. Measuring Arms These are the extendable parts of the gauge that contact the inner wall of the bore. They can be adjusted to achieve a secure fit, allowing the gauge to be reliable even in varied conditions.

3. Calibration Rod Frequently found in higher-end models, calibration rods ensure the bore gauge is set to proper standards before measurements are taken.

4. Handle and Gauge Body These provide maneuverability and stability while measuring, ensuring consistent results.

How to Use a Dial Bore Gauge

Using a dial bore gauge accurately requires a systematic approach

1. Preparation Ensure the gauge is calibrated and clean. Any debris in the bore can lead to inaccurate measurements.

2. Insertion Carefully insert the gauge into the bore until the measuring arms gently touch the inner surface.

3. Adjustment Adjust the measuring arms to ensure they are snug against the wall of the bore. This is crucial for obtaining an accurate reading.

standard dial bore gauge

4. Reading Measurement Observe the dial indicator to read the measurement, which reflects the diameter at that specific point in the bore. For enhanced accuracy, measurements can be taken at various points along the bore.

5. Documentation Record the measurements for quality control and further analysis.

Applications of Dial Bore Gauges

Dial bore gauges are invaluable across several industries, including

- Automotive In manufacturing engine blocks and other components, ensuring that bores meet precise specifications is critical for performance and safety. - Aerospace Components in aircraft must adhere to strict quality standards, making the dial bore gauge an essential tool for quality assurance.

- Manufacturing Many other types of machinery and equipment require precise internal measurements to maintain functionality and ensure the interchangeability of parts.

Advantages of Using Dial Bore Gauges

The dial bore gauge offers several advantages that make it a favored choice among engineers and machinists

1. Precision The design allows for high accuracy in measurements, which is crucial for quality assurance in engineering projects.

2. Ease of Use While calibration and setup are required, the actual usage of a dial bore gauge can be relatively straightforward for trained personnel.

3. Portability Most dial bore gauges are compact and easy to transport, facilitating measurements on-site or in diverse work environments.

4. Durability Typically made from robust materials, these gauges can withstand the rigors of a machine shop without losing their accuracy over time.

5. Versatility Suitable for various applications and industries, the dial bore gauge can adapt to different sizes and types of bores.

Conclusion

In conclusion, the standard dial bore gauge is an indispensable tool in the world of precision measurement. With its ease of use, accuracy, and versatility, it empowers engineers and machinists to maintain the high standards required in modern manufacturing. As technologies advance and the demand for precision increases, the dial bore gauge will undoubtedly continue to play a critical role in the industry, ensuring that every bore meets the stringent specifications necessary for today’s complex machines.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

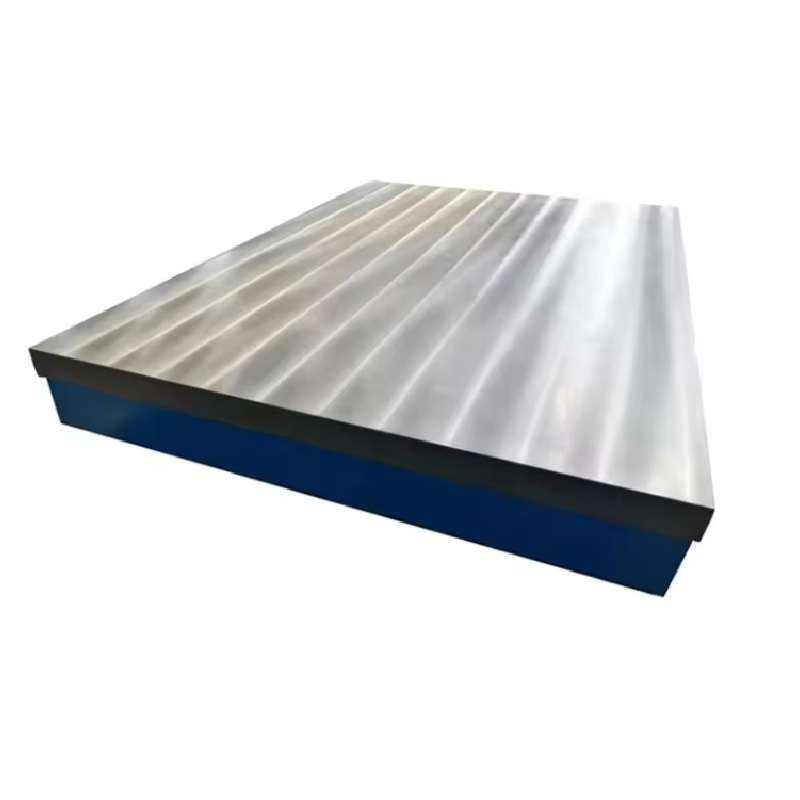

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS