መስከ . 21, 2024 17:58 Back to list

plain ring gages

Understanding Plain Ring Gages A Comprehensive Overview

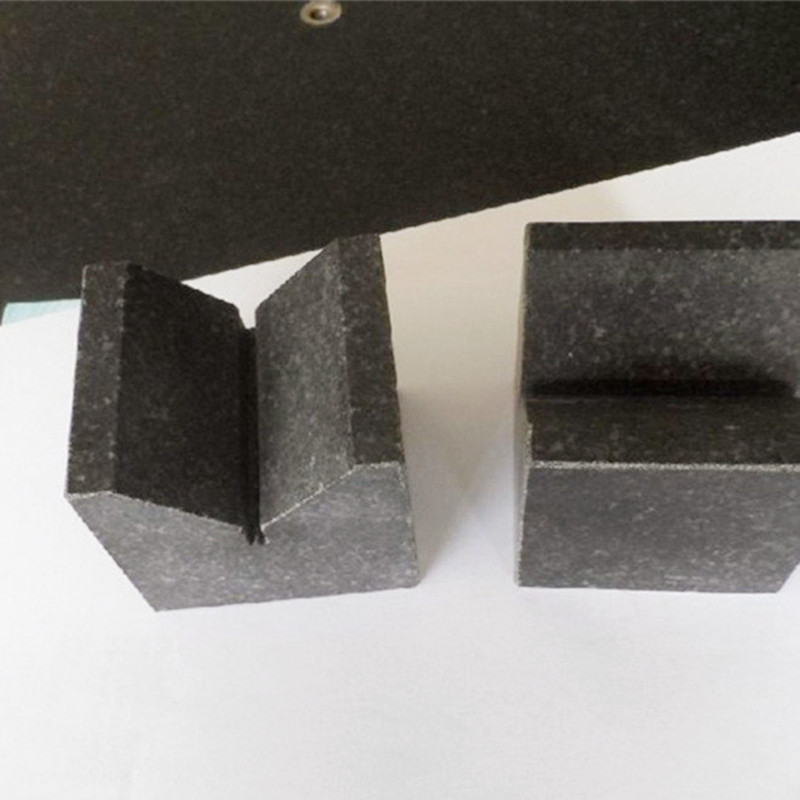

Plain ring gages, often referred to as ring gages or plain gages, are essential tools in the field of dimensional metrology. They serve a fundamental role in quality control and precision measurement across various industries, including manufacturing, engineering, and construction. These gages are primarily used to measure the internal dimensions of holes or the external dimensions of cylindrical components, ensuring that parts meet specified tolerances and fit correctly in assemblies.

Function and Design

A plain ring gage is typically a cylindrical tool that features precise inner and outer diameters. The inner diameter is usually designed to conform to a specific standard, which can be either a go or no-go designation. The go gage should fit onto a part that is within the specified tolerance, while the no-go gage will not fit onto that same part if it exceeds the acceptable limits. This binary measurement approach allows for quick and effective quality assessment, enabling manufacturers to catch defects early in the production process.

The materials used in manufacturing plain ring gages are often high-grade alloys or tool steels, which provide durability and resistance to wear. The gages are typically finished to a high degree of precision to ensure accuracy in measurements. They are often calibrated against national or international standards to ensure consistency and reliability.

Applications

Plain ring gages are widely used for various applications, including

1. Quality Assurance In manufacturing, it is crucial to ensure that parts meet design specifications. Plain ring gages allow inspectors to quickly verify dimensions during the production process.

plain ring gages

2. Assembly Verification When assembling components, it's vital that parts fit together correctly. Using plain ring gages helps in confirming that the parts will mate as intended, reducing potential assembly issues.

3. Tool Calibration Machining tools and devices require regular calibration to maintain performance and accuracy. Plain ring gages serve as benchmarks for checking the precision of various tools.

4. Research and Development Engineers and designers utilize plain ring gages during the prototype phase to refine designs and specifications before moving into full-scale production.

Advantages of Using Plain Ring Gages

One of the main advantages of using plain ring gages is their simplicity and ease of use. Operators can perform measurements quickly with minimal training. The binary nature of gage reading—pass or fail—eliminates ambiguity in the measurement process. Additionally, their robustness allows for repeated use over time, making them a cost-effective solution for consistent measurement needs.

Conclusion

In summary, plain ring gages are indispensable tools in the realm of precision measurement. Their role in quality control and assurance in manufacturing and engineering is crucial for producing high-quality products that adhere to stringent specifications. As industries continue to emphasize precision and reliability, plain ring gages will remain vital in ensuring that manufacturing processes meet the demands of modern technology and consumer expectations. The continued evolution of these gages will contribute to more efficient and accurate methodologies in various applications, solidifying their place as a cornerstone of quality assurance in manufacturing and engineering.

-

Welding Table Cast Iron Surface Finish GuideNewsJul.01,2025

-

Valve Types for Industrial ApplicationsNewsJul.01,2025

-

Types of Strainer for Industrial ApplicationsNewsJul.01,2025

-

Types of Bore Gauge for Precision MachiningNewsJul.01,2025

-

Safety Standards in Welding Fabrication Table Manufacturing ProcessesNewsJun.30,2025

-

Impact of Temperature Fluctuations on Ring Gauge AccuracyNewsJun.30,2025

Related PRODUCTS