ነሐሴ . 05, 2025 09:34 ወደ ዝርዝር ተመለስ

Comparing Different Butterfly Valve Types for Industrial Use

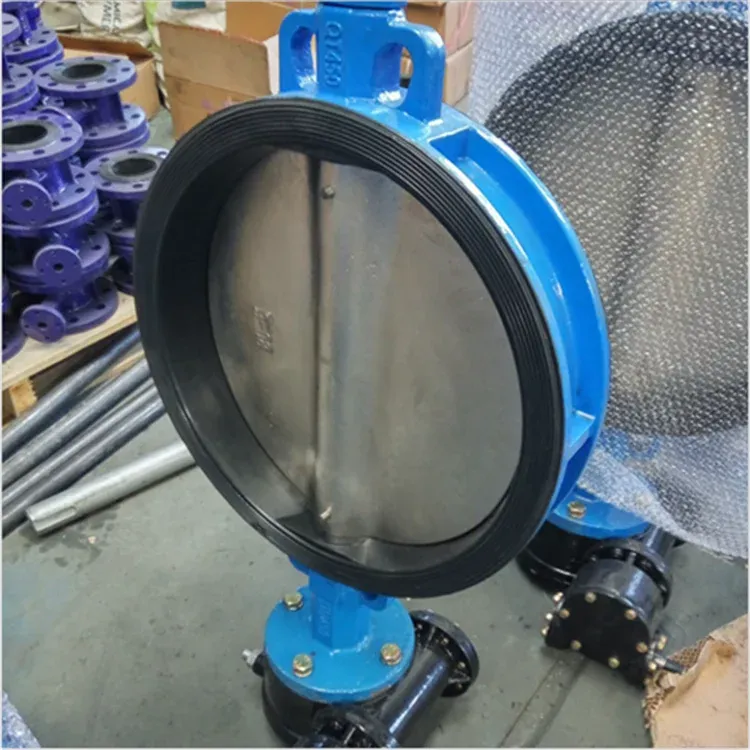

In industrial flow control systems, selecting the right valve type is crucial for operational efficiency, and understanding butterfly valve types is key to making informed decisions. As a wholesaler, offering a range of butterfly valve types and applications ensures that clients across industries can find suitable solutions, from water treatment to high-temperature industrial processes. Storaen (Cangzhou) International Trading Co., a leader in valve manufacturing, has developed diverse a butterfly valve models that combine precision engineering with durability, setting new standards in flow control. With a focus on quality, innovation, and tailored solutions, the company enables wholesalers to provide products that meet the specific needs of various industrial applications.

Butterfly Valve Types and Their Core Designs

Butterfly valve types are distinguished by their unique design features, each tailored to address specific operational requirements. These valves feature a disc centered in the pipe, with a simple structure that ensures easy operation. The disc rotates 90° to control flow, making them ideal for low-pressure applications such as water supply and drainage systems. Their compact design and cost-effectiveness make them a popular choice for industries where tight shutoff is not the primary concern.

|

Butterfly Valve Types |

Design Feature |

Primary Application |

|

Concentric |

Centered disc, simple 90° rotation |

Low-pressure water systems, HVAC |

|

Double Eccentric |

Two offsets for reduced friction |

Chemical processing, medium-pressure pipelines |

|

Triple Eccentric |

Three offsets for metal-to-metal sealing |

High-temperature industrial processes, flue gas ducts |

Butterfly Valve Types and Applications Across Industries

Understanding butterfly valve types and applications is essential for matching the right valve to specific industrial needs.

|

Industry |

Suitable Butterfly Valve Types |

Key Advantage |

|

Water and Wastewater |

Concentric |

Cost-effective, minimal leakage with soft seals |

|

Chemical |

Double Eccentric |

Corrosion resistance, reliable at medium pressures |

|

Power Generation |

Triple Eccentric |

High-temperature tolerance, metal-to-metal sealing |

A Butterfly Valve Material and Performance Features

A butterfly valve performance is heavily influenced by its material composition, which determines its suitability for different media and conditions. Storaen (Cangzhou) International Trading Co. offers valves with bodies made from HT300 cast iron , WCB carbon steel , and 316L stainless steel.

|

Component |

Material Options |

Performance Benefit |

|

Body |

HT300 cast iron, WCB carbon steel, 316L stainless steel |

Adaptability to different temperatures and media |

|

Seal |

NBR/EPDM (soft), stainless steel + graphite (hard) |

Leakage control and resistance to wear/abrasion |

|

Actuation |

Manual, pneumatic, electric, hydraulic |

Flexibility in operation, from simple to automated systems |

Storaen (Cangzhou) International Trading Co. Customize Butterfly Valve Types Capabilities

Storaen (Cangzhou) International Trading Co. stands out for its ability to customize butterfly valve types to meet specific client requirements, enhancing their appeal across diverse markets.

|

Customization Aspect |

Range of Options |

Client Benefit |

|

Sizing |

DN40 to DN1200, custom sizes available |

Perfect fit for any pipeline system |

|

Connections |

Wafer, lug, flanged, welded |

Compatibility with international standards |

|

Materials |

Various body and seal materials |

Optimal performance for specific media |

Butterfly Valve Types FAQS

What defines different butterfly valve types?

Different butterfly valve types are defined by their design features, particularly the number of eccentric offsets. Concentric valves have a centered disc, double eccentric valves have two offsets to reduce friction, and triple eccentric valves add a third offset for metal-to-metal sealing. These design differences determine their suitability for various pressure, temperature, and media conditions, from low-pressure water systems to high-temperature industrial processes.

How do butterfly valve types and applications align?

Butterfly valve types and applications align based on the specific needs of the industry or process. Concentric valves are used in water and wastewater treatment due to their cost-effectiveness and simple operation. Double eccentric valves are ideal for chemical processing, where corrosion resistance and medium-pressure handling are required. Triple eccentric valves are suited for power generation and high-temperature applications, as their metal-to-metal sealing can withstand extreme conditions.

What makes a butterfly valve suitable for industrial use?

A butterfly valve is suitable for industrial use due to its compact design, quick operation , and versatility. It can handle a wide range of media, from water to corrosive chemicals and high-temperature gases, depending on the material and design. Its ability to provide efficient flow control with minimal pressure drop makes it a preferred choice in industries where space and operational efficiency are critical.

How does material selection affect a butterfly valve performance?

Material selection significantly affects a butterfly valve performance. Body materials like HT300 cast iron work well for water and gas, while 316L stainless steel resists corrosion in chemical environments. Seal materials also play a role: soft seals ensure tight shutoff for water, while hard seals handle abrasive media and high temperatures. Choosing the right materials ensures the valve operates reliably in its intended application.

Why choose Storaen (Cangzhou) International Trading Co. for butterfly valve types?

Storaen (Cangzhou) International Trading Co. is a top choice for butterfly valve types due to its commitment to quality, customization, and industry expertise. The company offers a wide range of valves tailored to specific applications, with materials and designs that meet international standards. Its strategic location in Botou, a casting hub, ensures access to high-quality materials and skilled craftsmanship. With rigorous testing, reliable after-sales support, and a focus on innovation, Storaen (Cangzhou) International Trading Co. provides wholesalers with products that meet the diverse needs of industrial clients, ensuring long-term partnership success.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlዜናAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseዜናAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsዜናAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesዜናAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingዜናAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlዜናAug.05,2025

ተዛማጅ ምርቶች