ኅዳር . 19, 2024 17:34 Back to list

6 Percent Sanitary Butterfly Valve for Optimal Flow Control and Process Efficiency

Understanding 6% Sanitary Butterfly Valves Function and Applications

In industrial processes, particularly in the food, pharmaceutical, and beverage sectors, maintaining hygiene and efficiency is paramount. One of the most effective components in achieving these goals is the sanitary butterfly valve. Among various specifications and designs, the 6% sanitary butterfly valve stands out for its unique features and applications.

What is a Sanitary Butterfly Valve?

A sanitary butterfly valve is a type of quarter-turn valve that is used for regulating flow in a system. It consists of a circular disc or blade that rotates within a pipe and controls the flow of fluids by opening or closing the valve. The term sanitary indicates that these valves are designed to provide an optimal level of cleanliness and hygiene, which is critical in industries where contamination can have dire consequences.

6% Specification Explained

The designation 6% refers to a specific manufacturing standard which focuses on the valve’s materials, design, and the acceptable percentage of contaminants and imperfections that may affect its performance. Compliance with the 6% standard means that the valve has been tested and verified to ensure that it meets strict hygiene and performance criteria, making it suitable for sterile environments.

Key Features of 6% Sanitary Butterfly Valves

1. Material Composition Made from high-grade stainless steel, these valves are resistant to corrosion, ensuring longevity and reliability. The smooth internal surfaces prevent any build-up of bacteria or contaminants.

2. Easy Maintenance The simple design of a butterfly valve makes it easy to clean and maintain, a crucial feature for sanitary applications. Many models are designed to be easily disassembled, allowing thorough cleaning.

3. Flow Control The 6% sanitary butterfly valve provides excellent flow control. The quick operation—just a quarter turn—allows operators to swiftly open or close the valve, facilitating efficient fluid management.

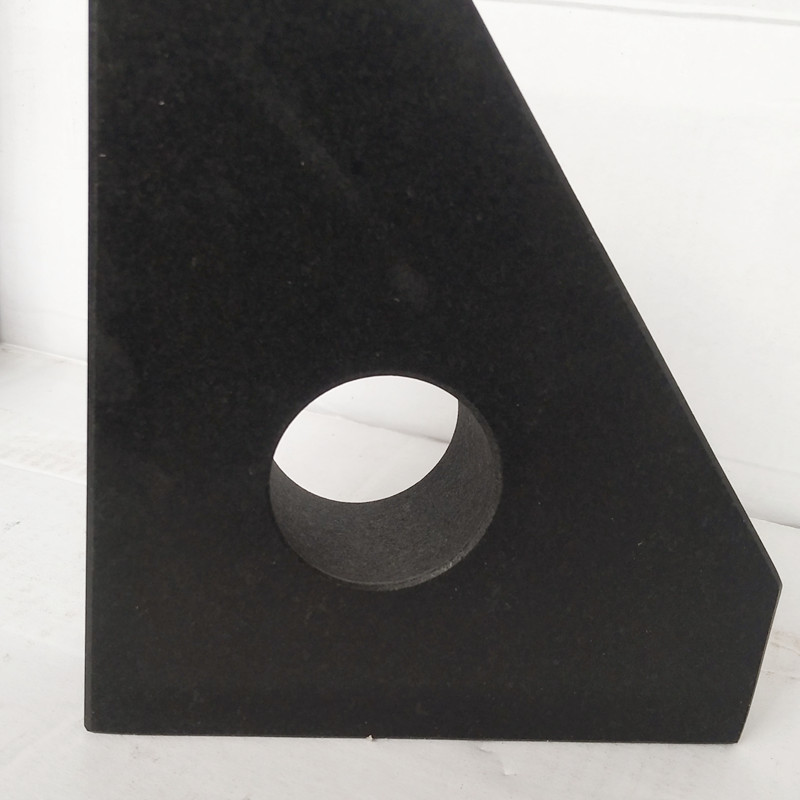

6 sanitary butterfly valve

4. Versatility These valves can handle a variety of fluids, including slurries, gases, and viscous liquids. This versatility makes them ideal for diverse applications across different industries.

5. Pressure and Temperature Tolerance Designed to operate effectively under varying pressure and temperature conditions, 6% sanitary butterfly valves can maintain performance in demanding environments.

Applications in Various Industries

Sanitary butterfly valves are employed in numerous applications, notably in

- Food Processing In this industry, maintaining stringent hygiene standards is essential. Sanitary butterfly valves are commonly used to manage the flow of liquids—such as milk, juices, and sauces—while preventing contamination.

- Pharmaceuticals The rigorous standards of pharmaceutical manufacturing necessitate components that meet strict compliance for cleanliness. These valves help in managing the flow of active ingredients and solvents.

- Beverage Production The beverage industry also relies on 6% sanitary butterfly valves to ensure that drinks are processed in a contamination-free environment while maintaining flavor and quality.

Conclusion

In summary, the 6% sanitary butterfly valve is an essential component in the landscape of industrial hygiene and efficiency. Its robust construction, ease of maintenance, and adaptability make it an invaluable tool for industries where the purity of processes is non-negotiable. By understanding and implementing these specialized valves, businesses can enhance their operations while ensuring the highest standards of cleanliness.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS