Jun . 06, 2025 10:47 Terug na lys

Choosing the Right Measuring Tool for Industrial Applications

Accurate measurement forms the backbone of quality assurance in modern manufacturing and engineering processes. The strategic selection of measuring tools significantly influences product quality, operational efficiency, and overall production costs across various industries. Manufacturers must carefully assess their measurement requirements to identify the most suitable engineering measuring tools and precision measuring tools that deliver the optimal balance of accuracy, reliability, and cost-effectiveness while complying with industry regulations.

Key Considerations for Industrial Measurement

Selecting appropriate measuring tools demands thorough evaluation of multiple critical parameters. The required precision level serves as the primary determinant - while certain applications may tolerate moderate accuracy, others necessitate extremely tight tolerances achievable only with specialized precision measuring tools. Environmental conditions represent another vital consideration, as factors like thermal variations can substantially affect the performance of engineering measuring tools. The nature of measured materials also guides measuring tool selection, particularly when dealing with delicate surfaces that may require non-contact measurement approaches.

Precision Measuring Tools for Critical Applications

Industries with stringent quality requirements rely heavily on advanced precision measuring tools. Coordinate measuring machines stand out among engineering measuring tools, delivering exceptional dimensional accuracy through sophisticated probing technology. Optical measurement systems and laser-based instruments enable comprehensive geometric analysis, while specialized surface analyzers provide detailed finish characterization. These high-end measuring tools typically incorporate advanced features to compensate for environmental variables, ensuring measurement consistency in challenging industrial settings.

Engineering Measuring Tools for Dimensional Accuracy

For routine measurement tasks, robust engineering measuring tools offer the ideal combination of precision and practicality. Modern digital measurement instruments provide enhanced readability, while traditional mechanical gauges maintain their importance for specific applications. Height measurement systems establish reliable reference planes, and specialized bore measurement devices verify hole characteristics. Contemporary versions of these precision measuring tools increasingly integrate data connectivity features, facilitating seamless quality documentation.

Versatile Measuring Tools for General Use

Fundamental measuring tools continue to serve essential functions in industrial environments for preliminary assessments. Linear measurement devices offer quick dimensional references, while angular measurement instruments handle orientation verification tasks. Leveling devices assist with alignment operations across various production areas. While these basic engineering measuring tools may not match the capabilities of advanced systems, their simplicity and durability ensure their ongoing relevance in manufacturing facilities.

FAQS about Industrial Measurement Solutions

When is it appropriate to transition from basic to precision measuring tools?

The shift to precision measuring tools becomes imperative when production requirements demand exceptionally tight tolerances or when measurement consistency proves crucial to product functionality. Sectors with rigorous quality standards typically implement these advanced engineering measuring tools as fundamental components of their quality systems.

Which engineering measuring tools should a quality control facility prioritize?

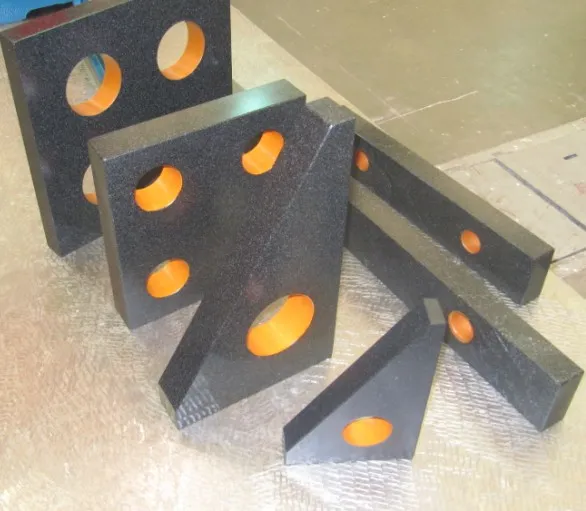

A comprehensive quality lab requires a granite reference surface with accompanying measurement equipment, various dimensional gauges, alignment indicators, and profile measurement systems. Modern digital iterations of these precision measuring tools are progressively favored for their automated documentation capabilities.

How do environmental conditions influence precision measuring tools?

Thermal effects pose the most significant challenge for precision measuring tools, with minor temperature variations potentially introducing substantial measurement deviations. Maintaining controlled environments proves essential when working with sensitive engineering measuring tools to preserve measurement accuracy.

Are digital measuring tools superior to traditional mechanical versions?

While digital measuring tools provide advantages in data management, conventional mechanical engineering measuring tools retain value for their robustness and reliability. Quality assurance protocols often mandate maintaining mechanical variants of precision measuring tools as reference standards.

What maintenance practices ensure optimal performance of engineering measuring tools?

Proper care of engineering measuring tools involves regular cleaning, appropriate storage conditions, scheduled verification procedures, and contamination prevention measures. Both elementary measuring tools and sophisticated precision measuring tools necessitate adherence to manufacturer-prescribed maintenance protocols.

-

Why the Right Angle Ruler Reigns in MetalworkingNuusJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNuusJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNuusJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNuusJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNuusJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNuusJul.21,2025

Verwante Produkte